Autonomously Generated Routines

The navigate-at-scale program is designed to autonomously generate routines for the required

devices, specifically the robot arm and motor, in order to automate the sample handling process.

These routine-generation procedures operate using critical data about the experiment setup, such

as the loading zone and microscope position in the Cartesian space, design specifications such as

vial height, and other such parameters. This allows for the application of this program to many

reconfigurable environments. Consider if the robot arm or carousel subsystems must be

repositioned or a new microscope or environment has been setup. Simply relocate the critical

loading zones using the robot arm and update the configuration data

accordingly, which can be found in the

autonomous_robotic_sample_handling/config/configuration.yaml file. The

navigate

program can continue running as expected.

Note

While the design-based solution is defined and discussed in this section, it has not been completed to function for all reconfigurable environments. As the precision of the routines would also be dependent on the precision of all measurements associated with the design approach, the manual tuning approach was selected as the primary focus of this project.

Reference Frames

Tool Reference Frame (TRF). This is relative to the gripper itself. positive Z is in the direction of the gripper fingers, positive X is downwards, and positive Y is to the left of the gripper. Euler angle rotations are defined as Rx, Ry, Rz, where Rx is the rotation about the X-axis, Ry is the rotation about the Y-axis, and Rz is the rotation about the Z-axis.

World Reference Frame (WRF). This is relative to the robot arm base. Positive Z is vertical up, X is forward, Y is to the left. Euler angle rotations are defined as Rx, Ry, Rz, where Rx is the rotation about the X-axis, Ry is the rotation about the Y-axis, and Rz is the rotation about the Z-axis.

The General Routine Procedure

To generate routines for the robot arm and other devices, it was required to design a general routine that all routines would emulate, following some set of operating guidelines. These operating guidelines are built upon a set of conditions required for safe and efficient operation of the system. Combined with other operational parameters and environmental conditions, appropriate control routines can be developed for automated sample handling.

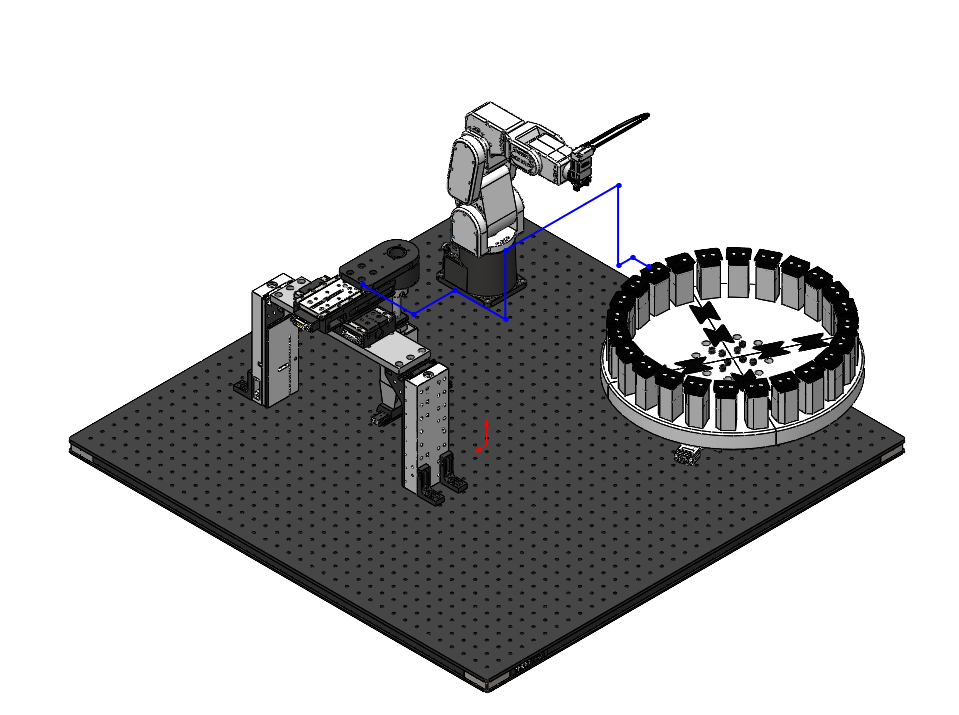

The general routine can be described as follows. A visual of the end-effector path throughout the first half of the routine is also provided below:

The robot arm homes to the ‘zero joints’ position.

The robot arm moves toward the loading zone of the carousel, positioning itself in front of the loading zone by a distance, engage_header_distance.

This parameter, defined by the length of the gripper fingers plus the thickness of the gripper, represents a minimum distance the robot arm should maintain before moving forward to grip the header plate.

The robot arm moves forward (+z in the tool reference frame, or TRF) by the distance engage_header_distance.

This sequence positions the gripper fingers exactly around the header plate, preparing for acquiring the sample.

This sequence simply performs a linear motion. The alignment for orientation, height, and related positioning all occurs in the previous motion.

The robot arm grips the header plate.

A strict range for the close_gripper() function has not been devised, as the sensory feedback of the gripper has been satisfactory in closing the gripper effectively around the target header plater while limiting flex in the gripper fingertips.

In the automatic gripper torque mode, a second LED indicates when sufficient torque has been detected, indicating the presence of the substrate that you are trying to grab. This is located on the side of the gripper, and is adjacent to the LED that indicates that the gripper is powered on.

The robot arm lifts the header plate by a distance sample_height.

The sample height is a data parameter specified in the configuration.yaml file which represents the height of the sample below the header plate. This variable specifies how high a selected sample must be lifted in order to prevent collisions with the sample for future operations. The sample_height variable is primarily influenced by the length of the threaded rod, the sample insert size, and any desired tolerances.

The robot arm performs a vertical oscillation maneuver.

The vertical oscillation maneuver is a simple drip management technique in place to limit the amount of solvent that drips onto the operating environment space.

This maneuver is currently performed using sub-routine commands from the robot’s offline program storage, rather than directly within the plugin software. Specifically, the robot is capable of storing routines generated from within MecaPortal in its memory. These can then be called and executed from Python, as is done here.

The robot arm returns to the ‘zero joints’ position.

This is an intermediate step to reset all robot arm joints and positioning before proceeding operations.

The robot arm moves toward the microscope loading zone, positioning itself at a distance, engage_header_distance. The positioning of the robot arm is also lower in the WRF z dimension, by a distance z_tolerance.

The robot positioning is lowered by an additional factor z_tolerance here to position the held header plate below the opposite magnet fixed to the microscope. It is desirable to attach the sample (via the header plate) from the bottom of the microscope fixture. This avoids disruption from the magnets and keeps the sample secure until attached to the microscope for imaging.

The z_tolerance is a user-defined feature though it is dependent on the available operating space. A distance of 10 mm is currently assumed for this tolerance.

The robot moves forward and up, attaching the sample to the microscope.

The robot arm moves forward and up by the engage_header_distance and z_tolerance distances respectively.

The robot arm retracts backward (w.r.t. to the TRF) by the engage_header_distance.

The robot arm has now attached the sample and is waiting for the microscope to begin imaging the sample.

The robot arm moves forward (w.r.t. to the TRF) by the engage_header_distance and grips the sample.

The microscope has now completed imaging the sample and the robot arm prepares to remove the sample from the microscope.

The robot arm shears the sample off the microscope.

In order to remove the magnetically attached sample and header plate, a simple linear motion is performed, a clean shear. The force of the gripper and speed of the motion is sufficient to leave the microscope untouched and smoothly remove the sample.

The robot arm returns to the ‘zero joints’ position

This is an intermediate step to reset all robot arm joints and positioning before proceeding operations.

The robot arm moves toward the loading zone of the carousel, positioning itself on top of the loading zone by a distance, sample_height.

The robot arm positions the sample and header plate straight above the loading zone, aligned to lower it into place. The positioning of the header plate a distance of sample_height above the loading zone is to prevent the sample from colliding with the vials or carousel.

The robot arm opens the gripper, releasing the header plate.

The robot arm retracts from the loading zone.

Following the completion of a complete routine, the program either:

terminates, if the last sample has been processed.

- continues with the next sample in queue, should the queue be non-empty.

The motor rotates by 15 degree increments to the next sample’s loading zone.

Routine Generation Approaches

There are two primary approaches to generating autonomous routines for the navigate-based automated sample handling system:

- Design-Based Approach:

The design-based approach is based on geometric calculations of measured data, in which a series of measurements related to the desired actions are collected and the corresponding sub-routines formed.

- Manual-Tuning:

Alternatively, the critical locations for the experiment, such as the loading zone and the microscope staging area, can be identified by manually operating the robot arm using the Mecaportal software to the desired poses.

Warning

The design-based approach is currently incomplete, as it only operates with the carousel in directly in front of the robot. More detailed subroutines have not been built for the microscope staging area interactions either. As such, it is recommended to stick to the manual tuning approach for which extensive testing has been with for the system.

Critical Data

All data for the generation of control routines is held within the

configuration.yaml file, located within the plugin under the config

directory.

Note

The configuration data for this experiment is retained within this plugin for the isolation of this data. navigate tools are utilized to locate and acquire this data during operation with the larger navigate ecosystem. It is considered best practice to directly host these configuration files within the .navigate directory for future applications.

There are three major categories of critical data collected in the first iteration of this program. These are discussed in more detail below:

The most critical data refers to the robot arm poses for the loading zone and the microscope staging area. All routines are based off of these data points where the robot arm performs a series of actions.

Currently, all locations are devised with reference to the robot arm’s center base as the origin, to reflect the origin of the robot within Mecaportal. As discussed in the guide to manual tuning, the location updated in the

configuration.yamlrefers to the robot arm’s end-effector pose when the robot arm is in the desired position. This is the simplest strategy as the MoveLin() commands that position the robot arm within the critical location zones all operate on the robot arm’s local world reference frame.A feature has been set up to assume a non-zero robot base, should it be of interest to define all critical locations with respect to a global origin of the table or such. In such a case, simply find the difference between the critical location and the robot base to find the required movement of the robot arm within its local reference.

There exists a flag in the

configuration.yamlto enforce whether the manually tuned loading zone data should be used, or if the design-based approach results should be prioritized. It is currently set to true and should remain as such unless the design-based approach is adjusted.

The second set of critical data refers to the physical measurements of the system components and the environment. Data such as the thickness of the gripper, the length of the gripper fingertips, and other such measurements are critical to devise routines that avoid collision of the robot arm with the environment or the damaging of any samples.

Currently, design related component data is also included within this section. Data such as the vial height in the carousel or the carousel radius are required components for the design-based approach for routine generation. Note that such data is designed to simplify the required geometric calculations and not to focus on the component itself.

The final set of of critical data refers to the tunable parameters within this routine generation program. This data refers to variables such as the height of the sample, the distance to shear the sample, or the initial motor position for the loading zone. These values are subject to the user’s opinion or are dependent on the specific experiment setup.

Future Improvements

The autonomous routine generation program has been designed to be re-configurable for all environments. However some aspects of it require manual adjustment, something that would preferably be avoided. This specifically applies to modifications to parameters of the MoveLin() function calls within the autonomous script, as the remaining operations are based on the TRF and function irrespective of the robot arm orientation.

Consider ‘Step 2’ where the robot arm positions itself in front of the loading zone. The robot arm sends a command self.robot_arm_controller.move_lin(x - engage_header_distance, y, z, Rx, Ry, Rz). Here, the carousel is always assumed to be placed in front of the robot arm (where x > 0 in the WRF) and for this reason, the engage_header_distance value must be subtracted from the x parameter to safely position the robot. Otherwise, the robot arm would crash into the carousel. This becomes more prominent with the positioning of the microscope, traditionally placed in the left or right planes of the robot arm (y < 0 or y > 0 in the WRF) and both the shear direction must be adjusted to avoid selecting a position that would put the robot arm in error. Currently, this must be handled by the user directly, who would use their own understanding of the environment and orientation to determine a suitable direction and distance to shear the sample off the microscope staging area. An update to this system would utilize the relative orientation and pose of the robot arm and accordingly determine a suitable shear direction. An additional flag or parameter could override this if necessary.

Some parameters are currently hard-coded into the system and have not been updated after the testing phases. Update these in the prepare_config_data() and configuration setup. Determine suitable parameters of interest that could be of use for setting up experiments.

The use of intermediate checkpoints have been used to return the robot arm to a safe position and limit the possibility of the robot entering an error state. Intermediate checkpoints can also be used to enforce specific motions or avoid obstacles. Suppose the microscope staging area is in a position only reachable by the robot arm in one particular pose. A set of intermediate checkpoints may need to be provided to ensure that the robot arm can effectively reach that desired end pose.

This feature would require a set (or sets) of intermediate checkpoints that represent the sequence of poses that the robot arm must follow. The automation program would loop through this list, reaching each of these intermediate poses, before reaching the final pose.

It must be noted that the method of reaching this intermediate poses may be abstracted further, as to provide a command name along with the corresponding data (‘move_joints’, [0, 100, 0, 0, 0, 0]). This is simply to retain all data within the configuration.yaml file, though hard-coded sub-routines can be developed for such cases.

The generation of these routines is highly dependent on the configuration data and routines provided, given that the low-level robot arm commands, or the inverse kinematics, are directly handled by the mecademicpy API. Building an interface to more easily interact and program routines taking these into account will drastically improve the quality of the final routines.