ALSM/CTASLM Baseplate Assembly & Alignment

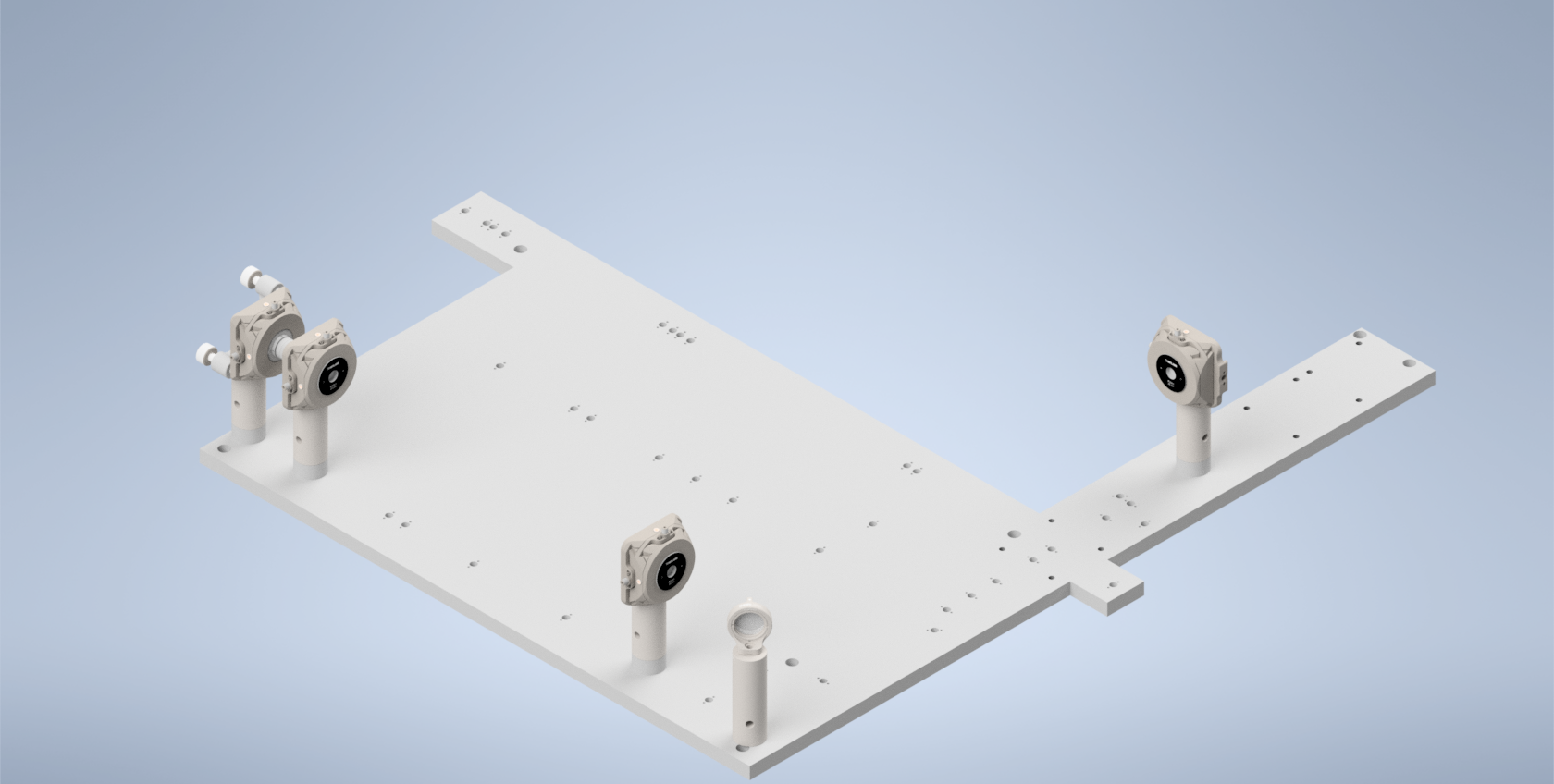

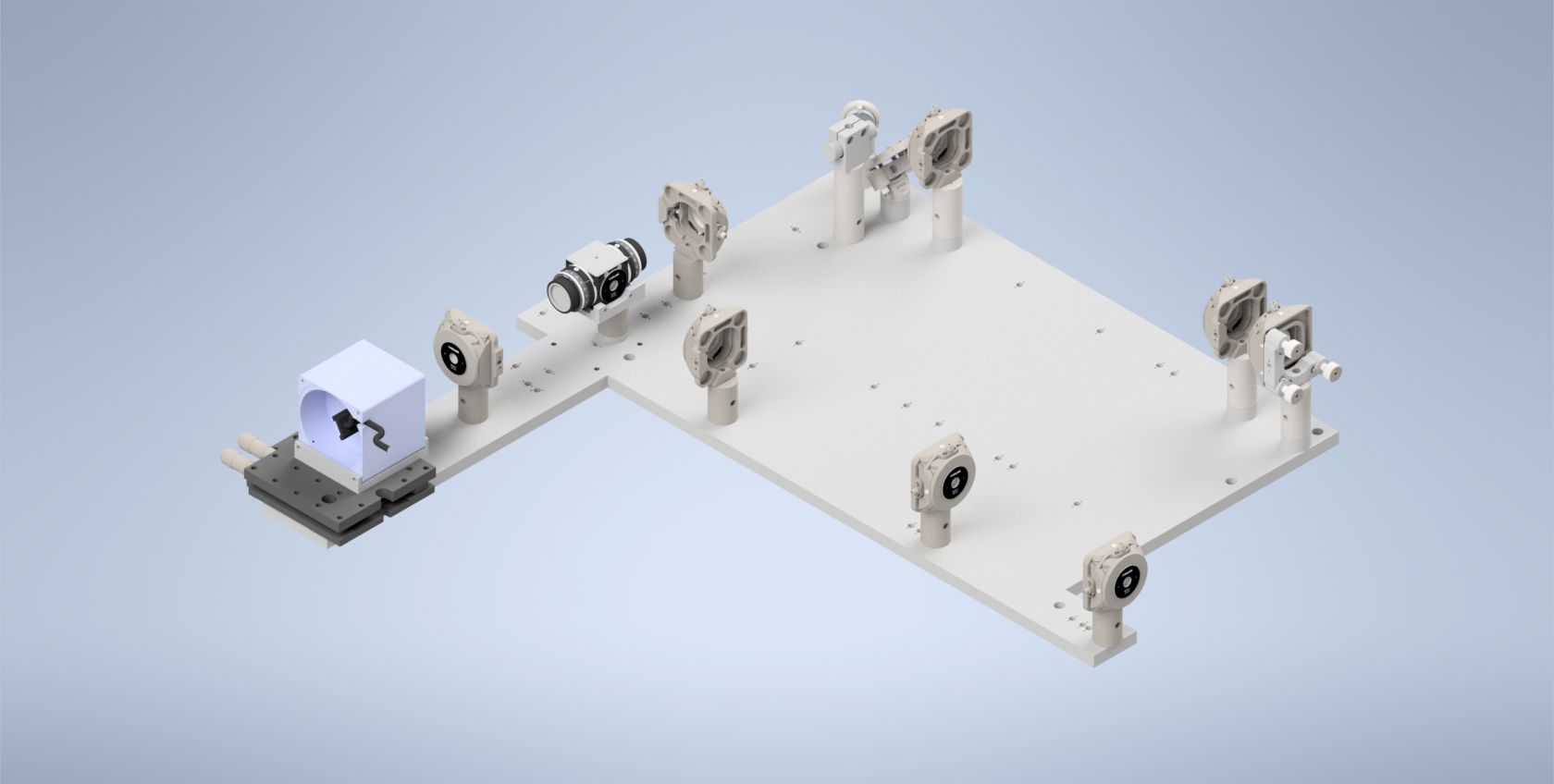

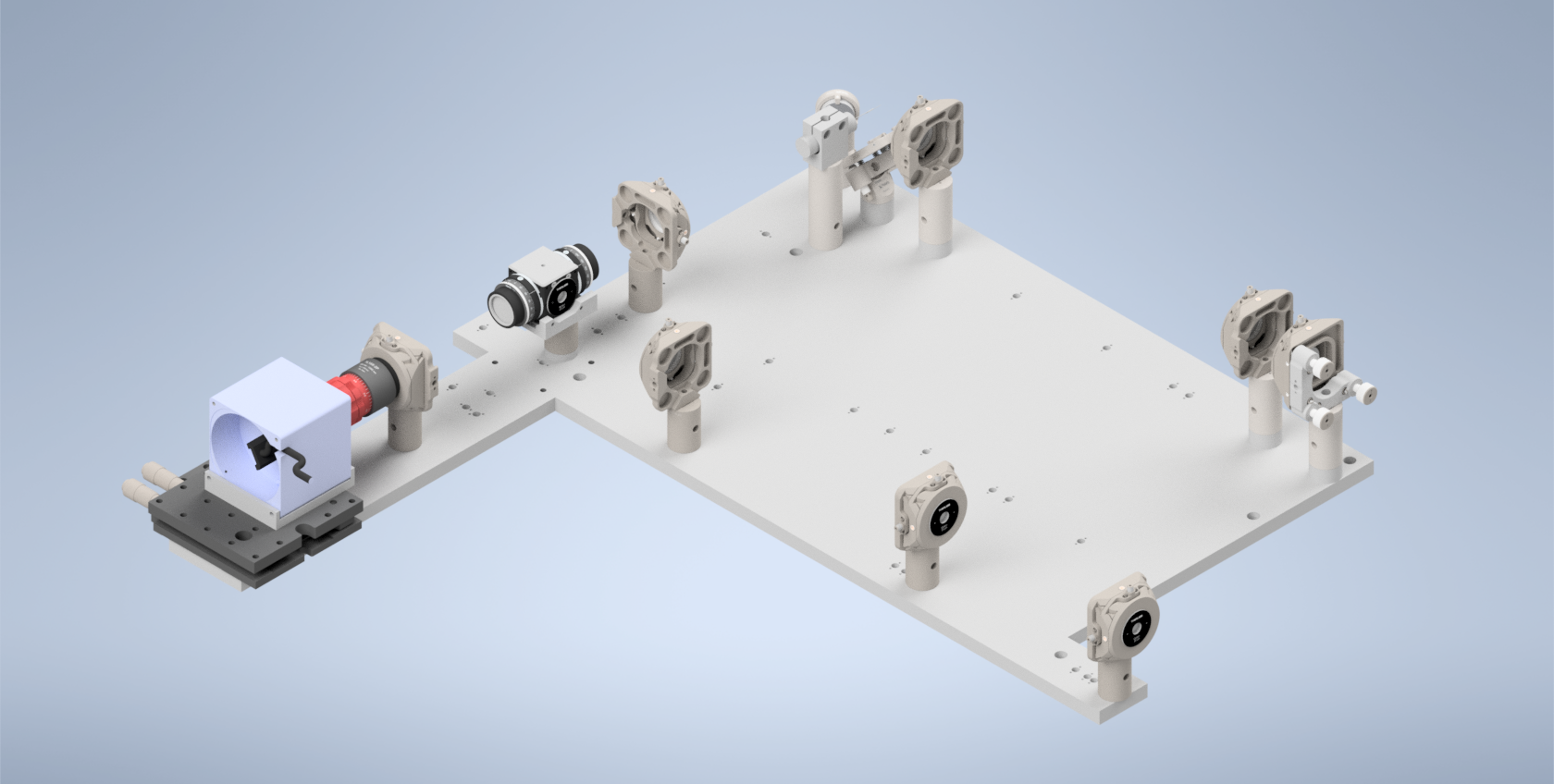

Available Configurations

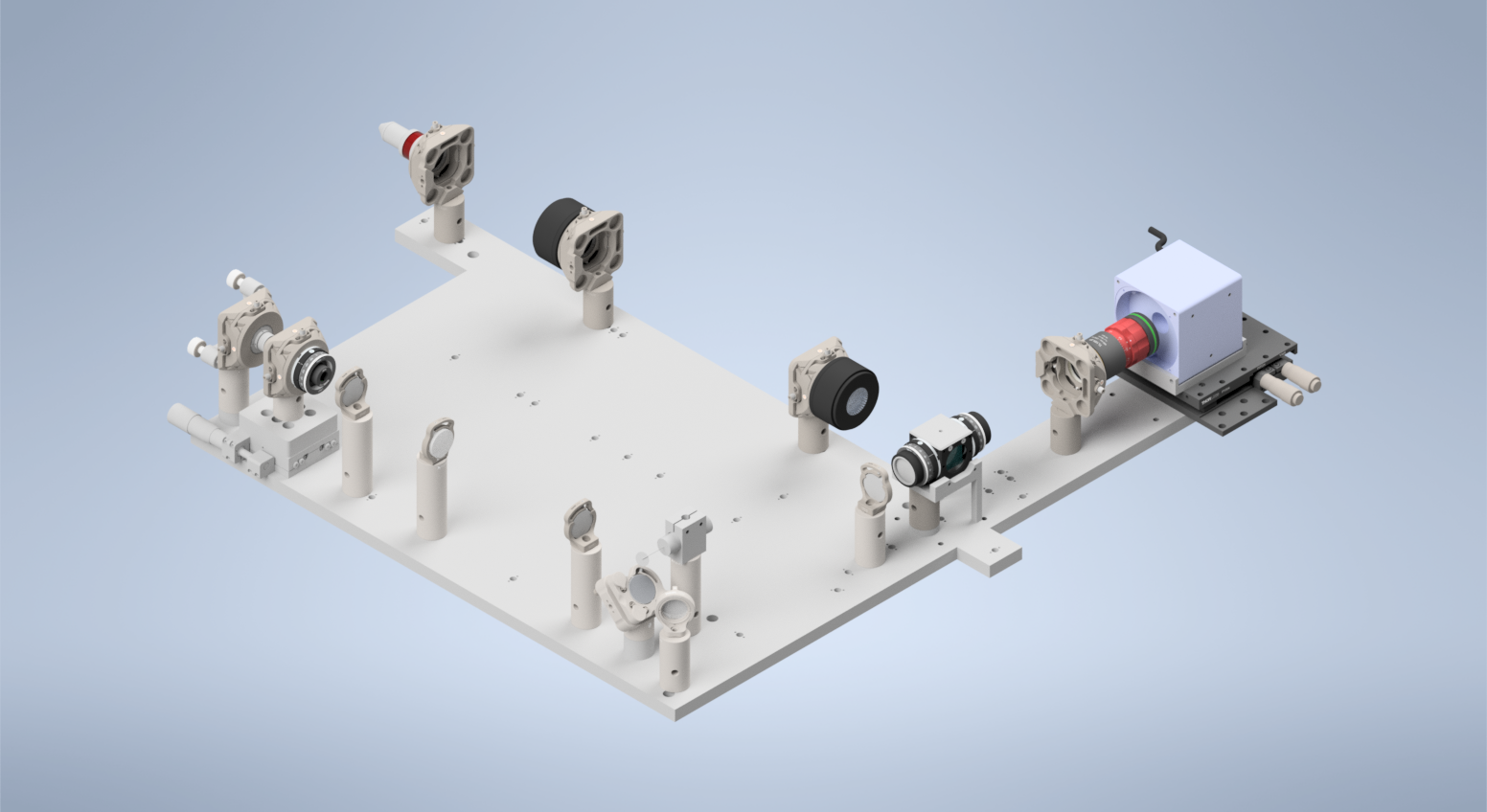

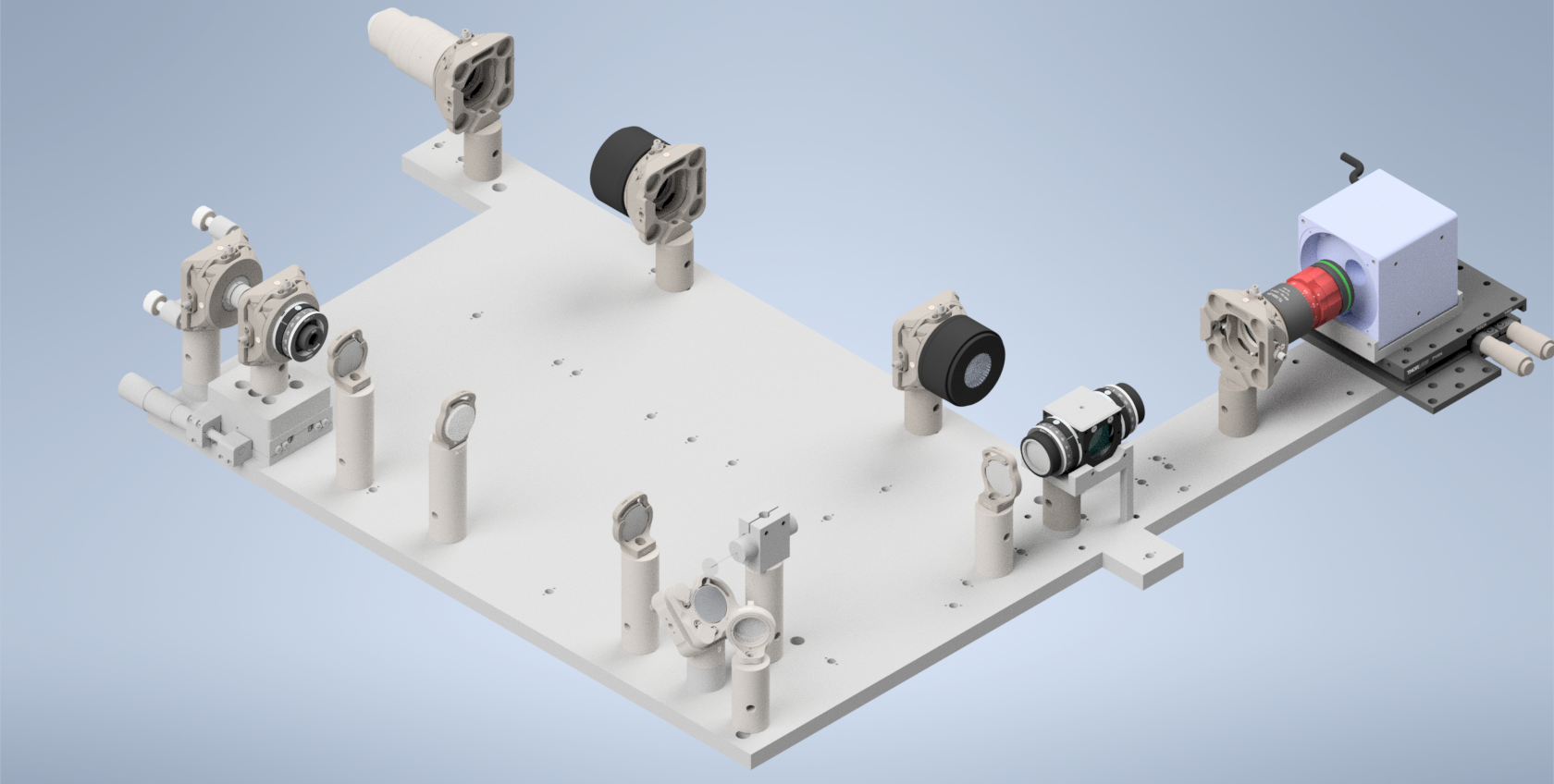

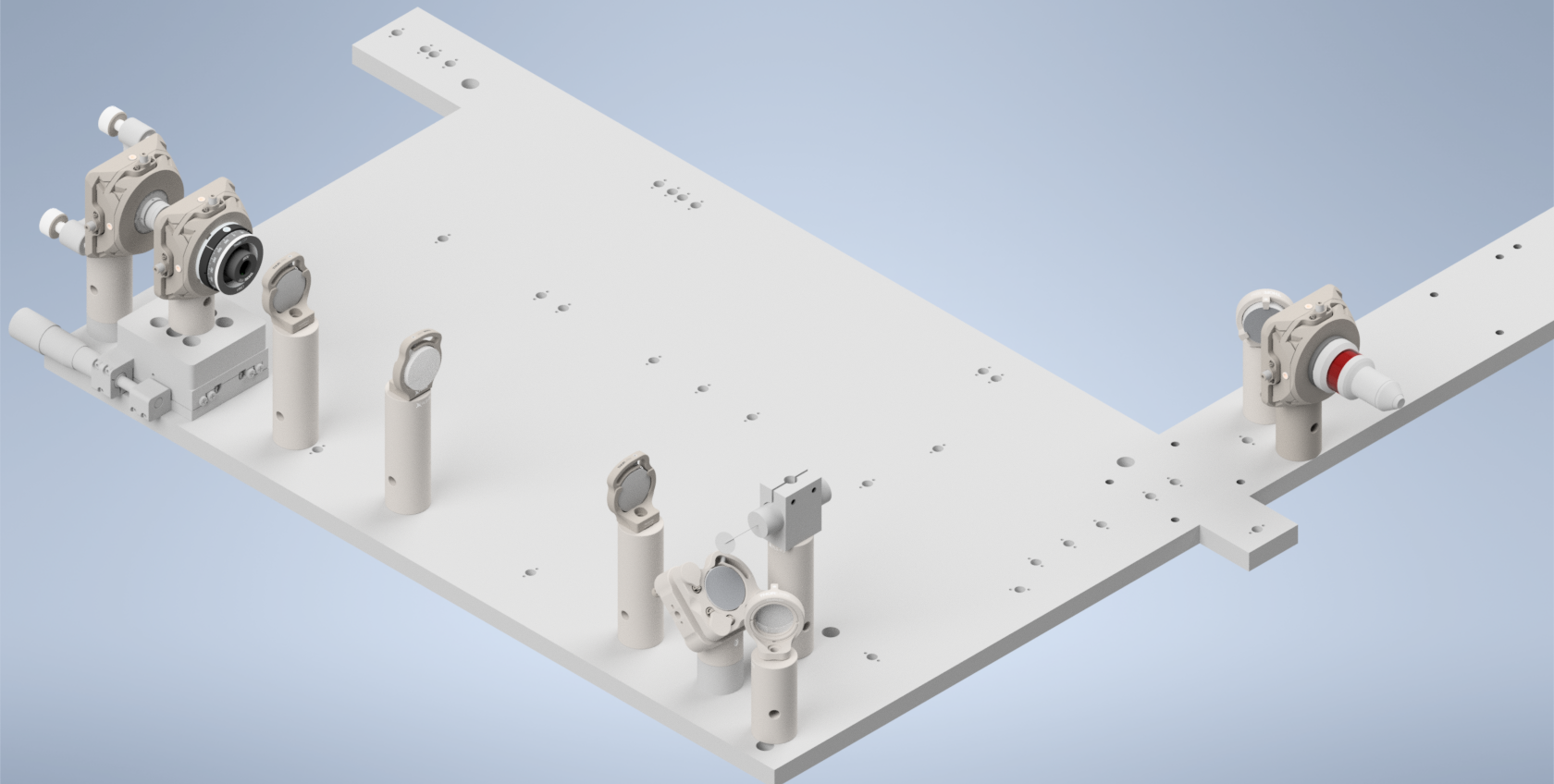

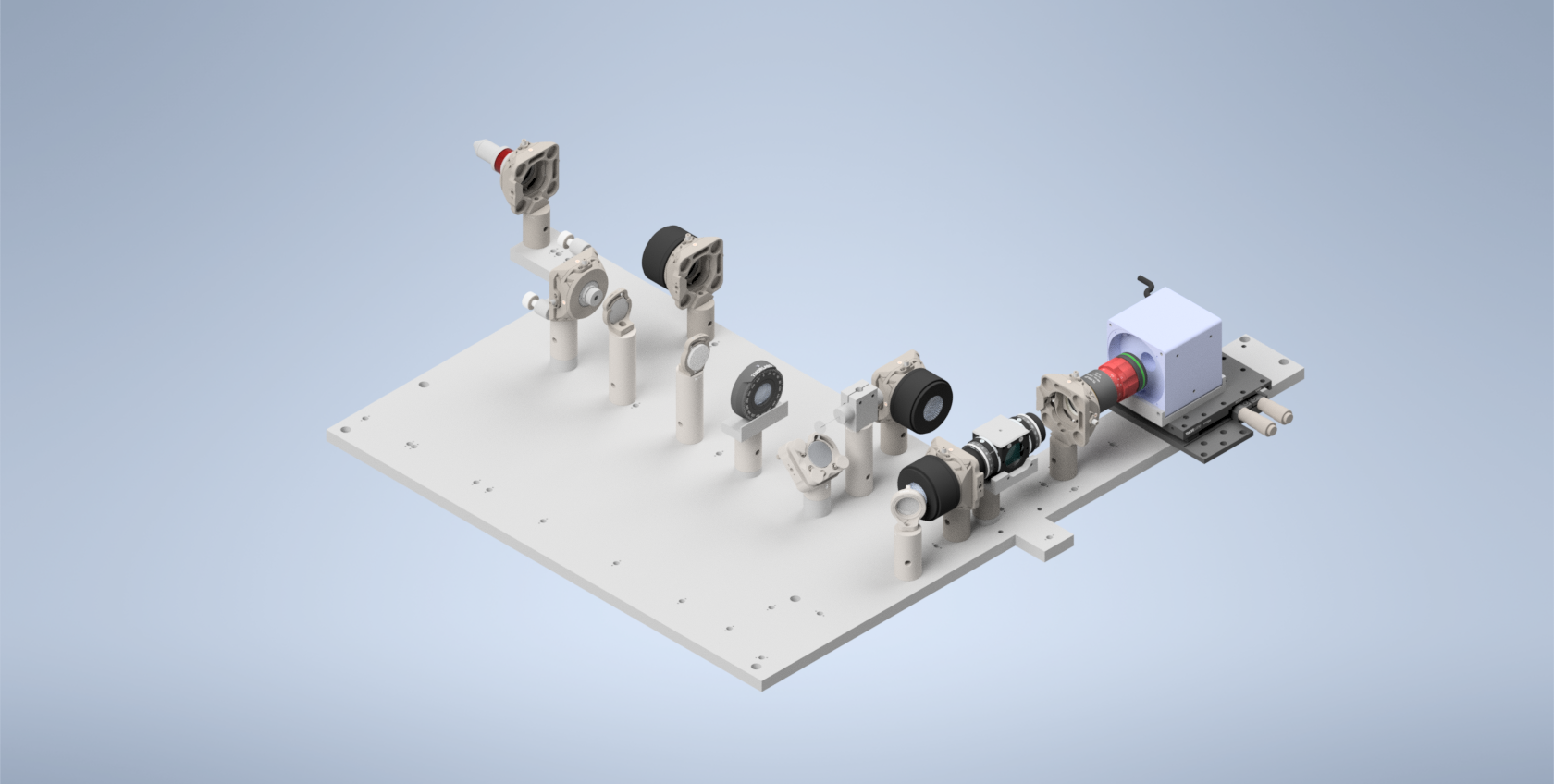

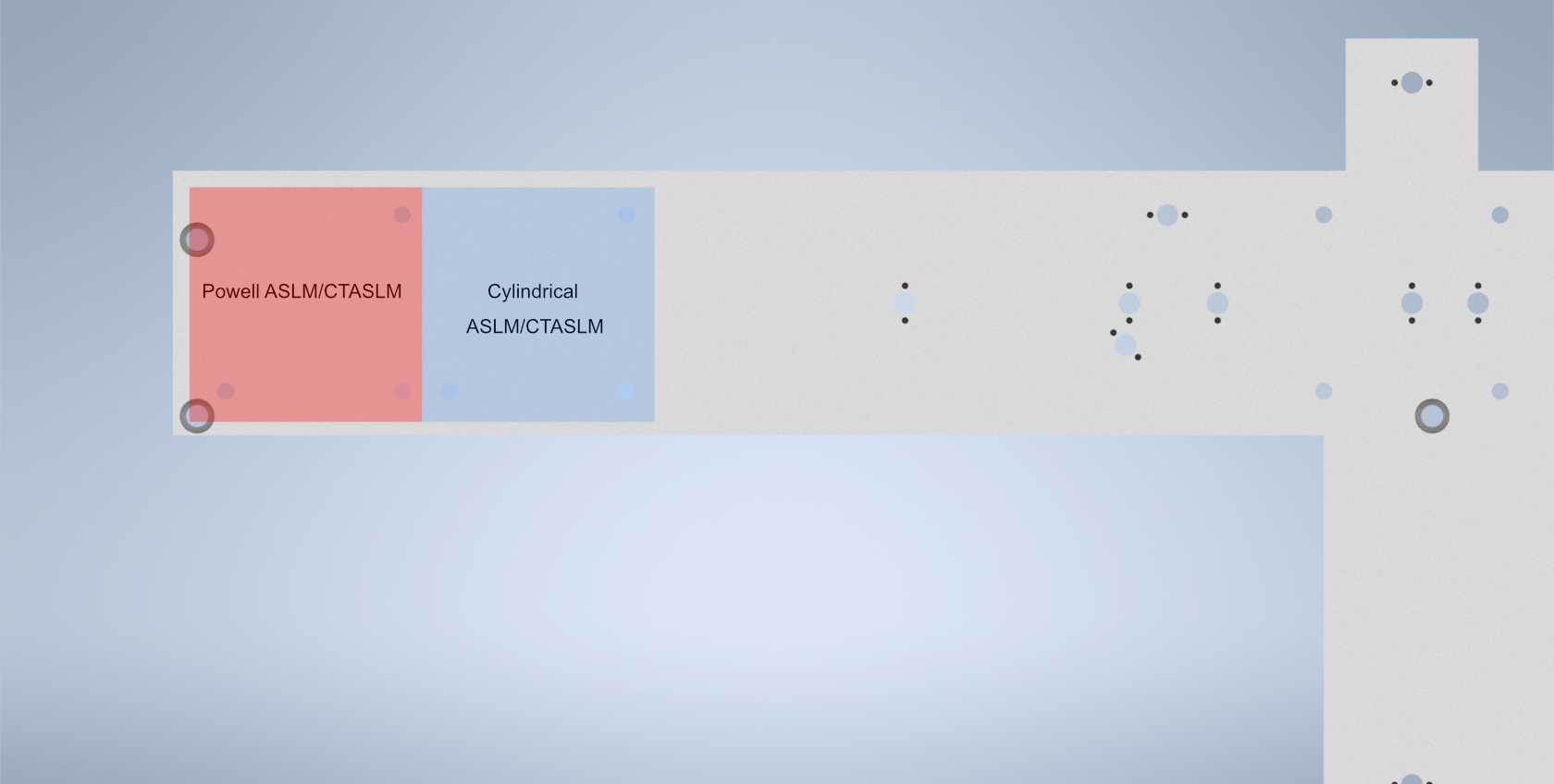

The current iteration of the baseplate provides 5 different possible imaging configurations: 2 using a cylindrical lens to form the light sheet (ASLM, CT-ASLM), and 3 using a Powell lens to form the light sheet (SPIM, ASLM, CT-ASLM) . Our primary focus in this section will be the construction and alignment of the Powell lens configurations, but the cylindrical configurations will follow a similar process.

Breakdown of Baseplate Holes

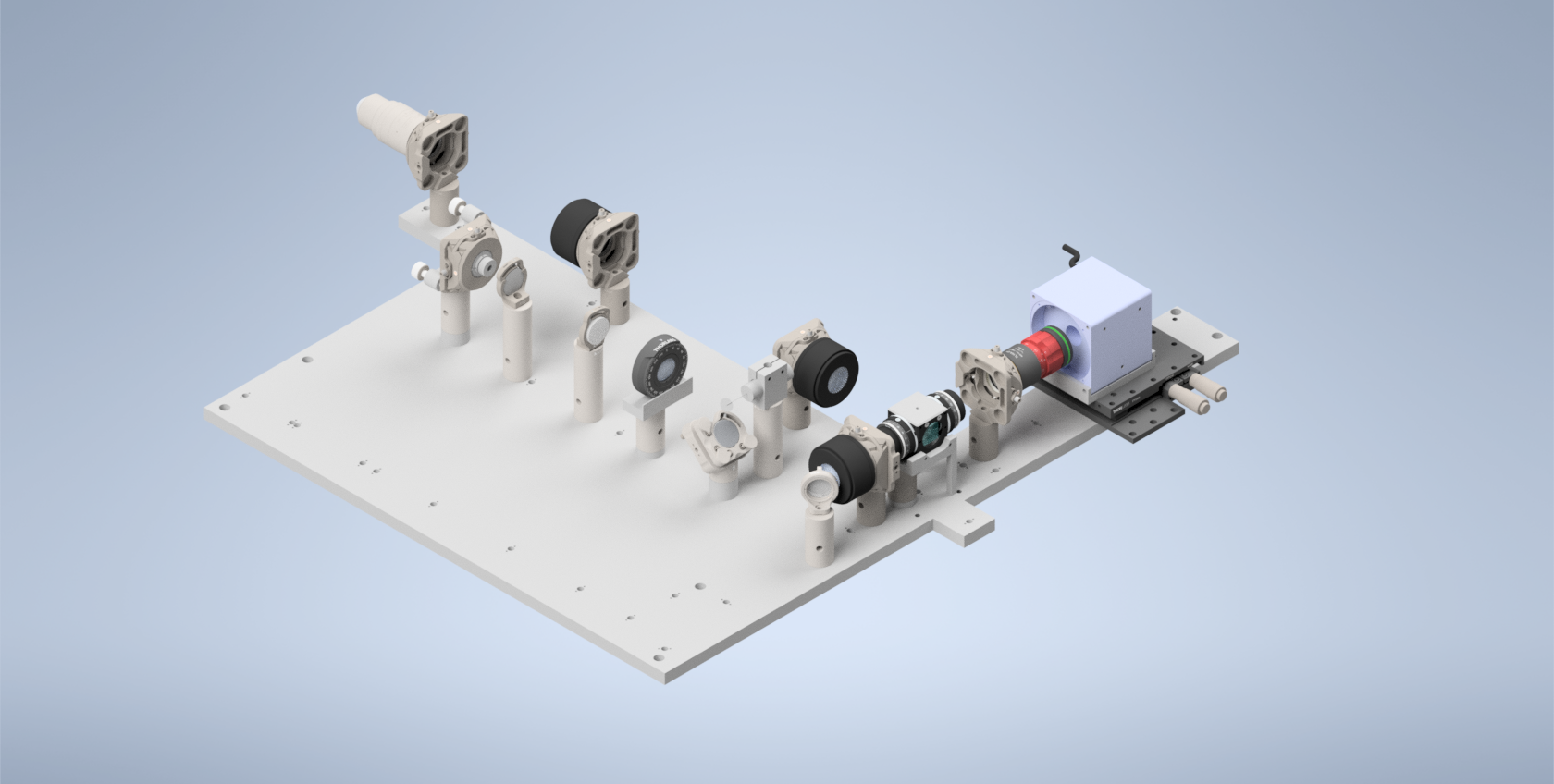

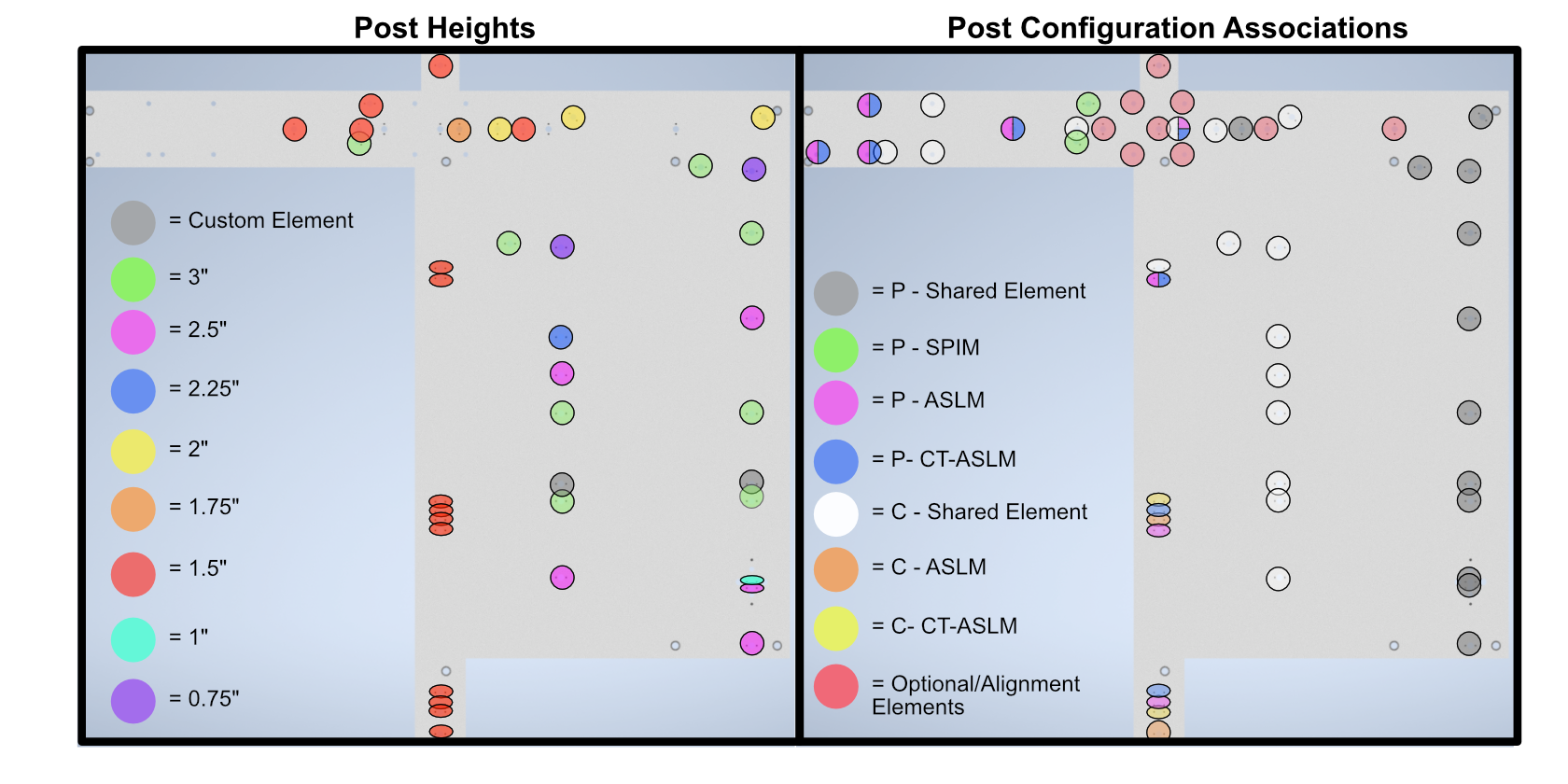

Here we show a breakdown of all the holes on the baseplate in terms of what configuration they’re designed for (Figure 1),the post height corresponding to those holes (Figure 1), and the elements corresponding to each hole (Figure 2). It should be noted that we include a couple additional holes on the baseplate for alternative component mounting schemes (Figure 2). Figure 2 also shows the orientation that each of the lenses should be in within the setup, where for the TTL tube lenses the orientation is shown based on the direction of the TTL labeling on the lenses themselves.

Figure 1: Labeled baseplate holes based on post height (left) and configuration (right)

Figure 2: Labeled baseplate holes based on what component is placed at each hole

Assembly

Assembly Overview

For the second iteration of our Altair baseplate system, the construction and alignment process is more involved than our first iteration, but should still be a straightforward step-by-step process.

Powell Lens Assembly

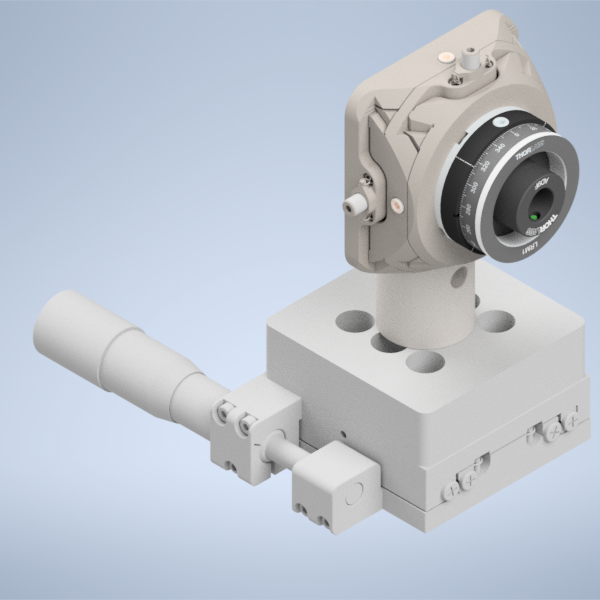

Our newest illumination path configurations utilize a Powell lens as the element that forms the light sheet profile itself instead of a cylindrical lens. Our mounting scheme for the Powell lens offers control over all 3 axes (x, y, and z), where the Polaris 1XY Mount covers x and y and the LNR25M covers z. We found that outside of the Polaris 1XY for centering the powell lens precisely on the beam, due to tolerances of the Powell lens from laserline we use, we also needed to adjust the distance between the Powell lens and L2 to have our physical system align with our simulations.

Step 1: Fixing the Powell lens into the AD9F Mount

For the first step, get a piece of optical tissue paper and the AD9F and Powell lens. Place the flat face of the Powell lens onto the tissue paper, and then place the AD9F onto the Powell lens such that the front surface of the smaller side of the AD9F is flush with the flat face of the Powell lens. Use the two mounting screws on the AD9F to secure the lens in place.

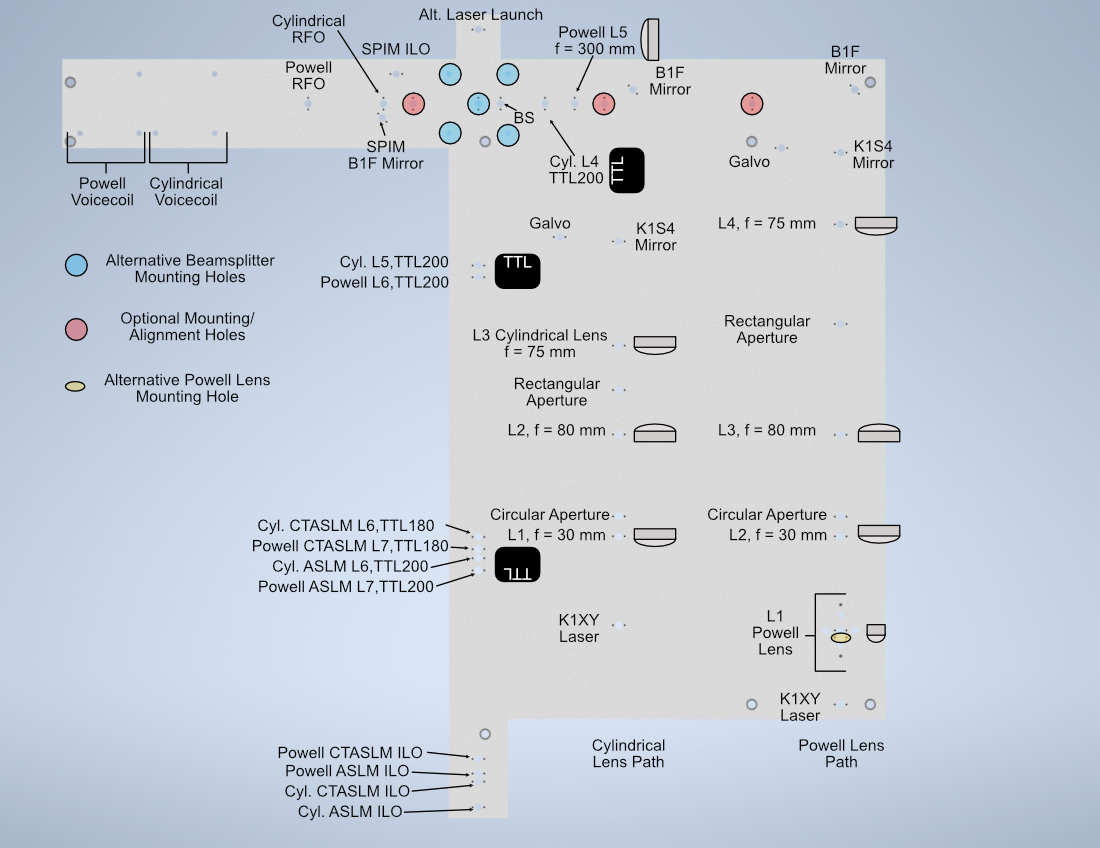

Step 2: Install the LRM1 rotation Mount into the Polaris 1XY

Screw the threaded portion of the LRM1 into the threaded hole on the Polaris 1XY until the back surface of the LRM1 is flush with the front of the 1XY.

Figure 1: Screwing the LRM1 into the 1XY

Step 3: Install the LNR25M onto the Baseplate

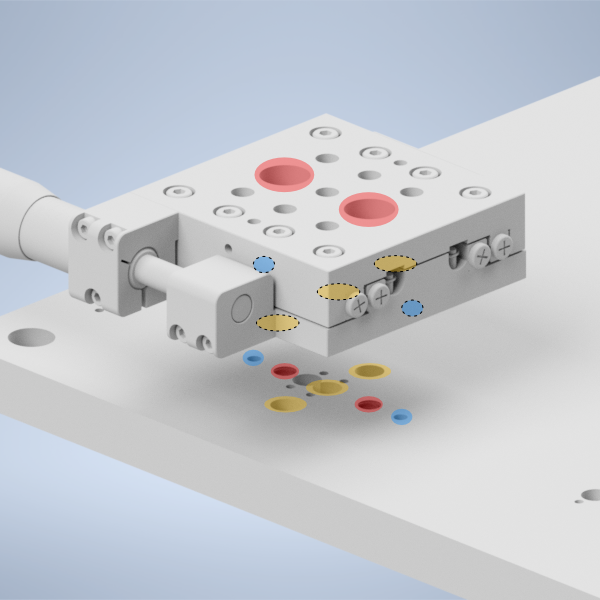

There are a variety of holes on the baseplate that one can use to fix the LNR25M in place. In the graphic below, the two holes in red on the top of the LNR25M allow you to thread 1/4-20 screws directly through the LNR25M into the threaded holes on the baseplate below. There are also two 3 mm-diameter dowel pins on the bottom of the LNR25M that have corresponding holes on the baseplate in blue. Finally, there are three holes on the baseplate in yellow that correspond to threaded holes on the bottom of the LNR25M, 1/4-20 screws can be used to secure the LNR25M through these holes the same way that one would fix the other Polaris posts on the baseplate in place.

Figure 2: placing the LNR25M onto the baseplate

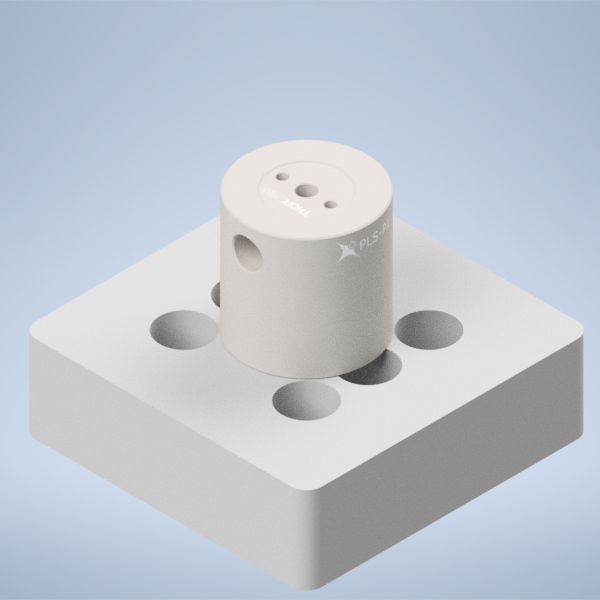

Step 4: Fix the 1” Polaris Post onto the LNR25M to Polaris adapter

Then take the LNR25M to Polaris adapter and using the same 2 mm dowel pins and 1/4-20 screws that the other Polaris posts in the system use, fix the 1” Polaris post onto the adapter by screwing in a 1/4-20 screw from the bottom of the adapter into the post.

Figure 3: placing the 1” Polaris Post onto the LNR25M Adapter

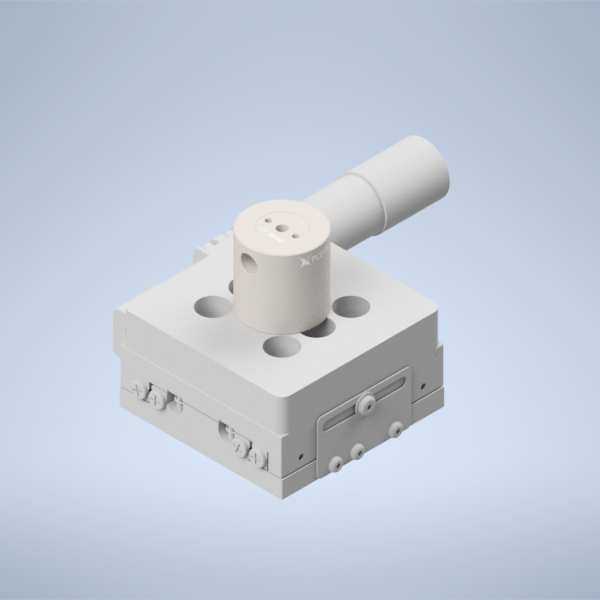

Step 5: Install the LNR25M to Polaris adapter onto the LNR25M

Then using the four holes on the top of the adapter surrounding the 1” post, place 1/4-20 screws in those holes and screw them into the top of the LNR25M

Figure 4: placing the LNR25M Adapter onto the LNR25

Step 6: Fix the Polaris 1XY onto the 1” Polaris post

Using a 8-32 screw and the 2 mm dowel pins, fix the Polaris 1XY onto the top of the 1” Polaris post assembly.

Figure 5: Fixing the Polaris 1XY onto the 1” Polaris Post

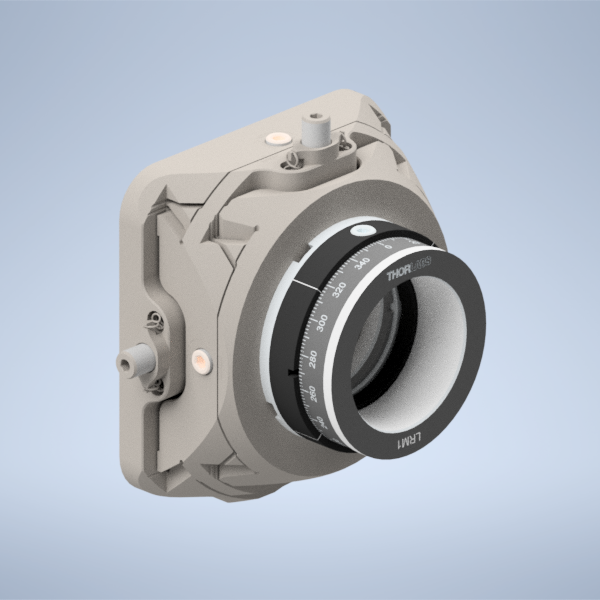

Step 7: Screw in the AD9F into the LRM1 mount until it’s fully threaded

Finally, screw in the AD9F fully into the LRM1 mount threading.

Figure 6: Threading the AD9F into the LRM1 mount

Voicecoil Assembly

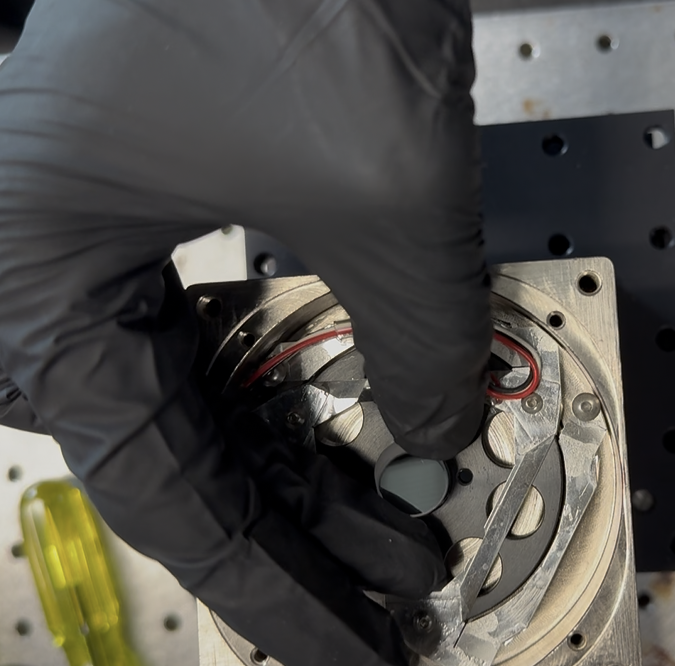

Step 1: Fixing the mirror into the voicecoil

Start by taking a 0.5” mirror and fixing it into the central hole on our voicecoil using UV-cured resin adhesive . Apply a thin layer of liquid resin to the back of the mirror, and place the mirror in the central voicecoil hole. Then using a UV flashlight, cure the resin to secure the mirror in place.

Figure 1: Placing the mirror into the voicecoil hole

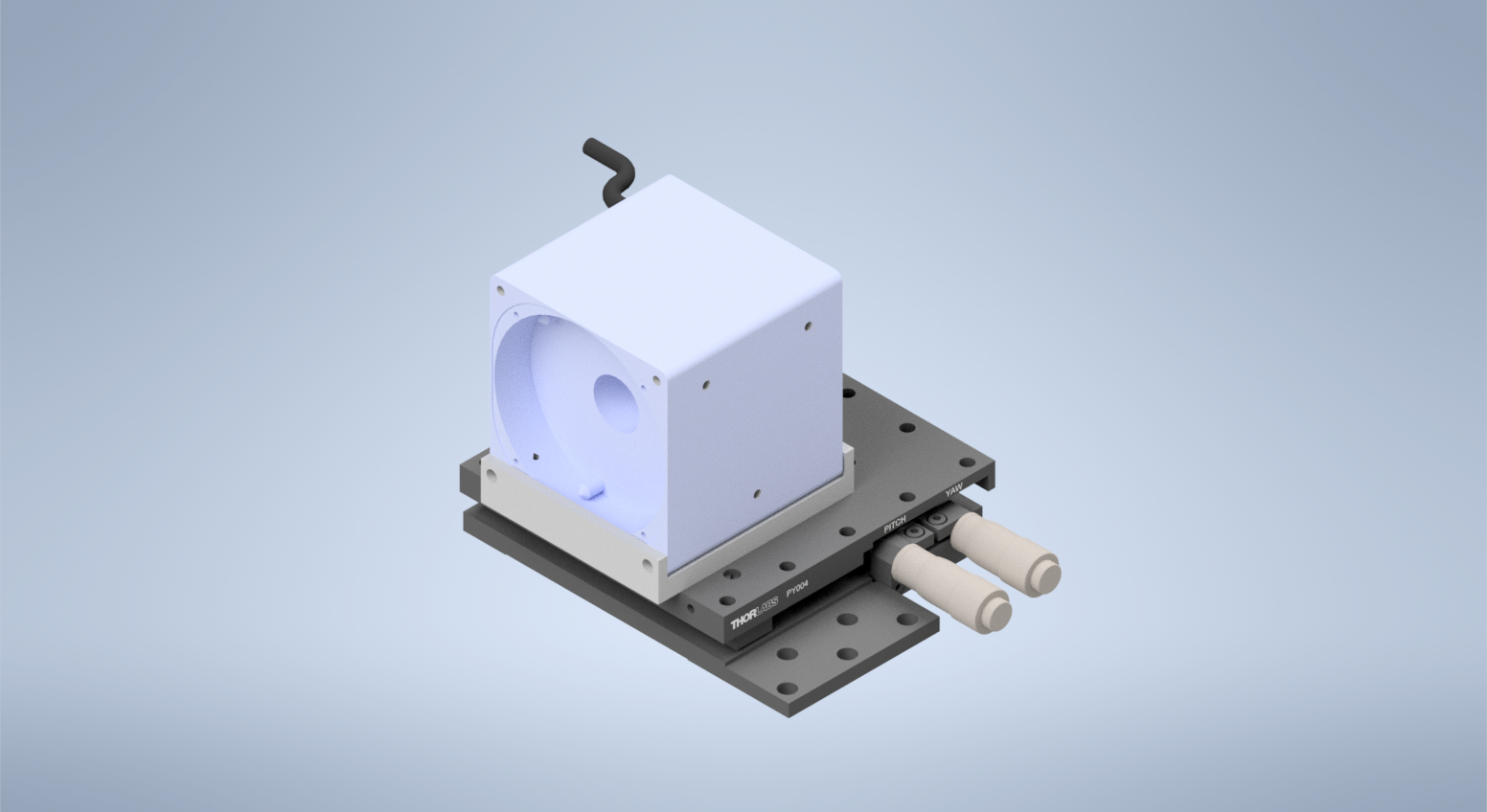

Step 2: Secure the PY004 onto the baseplate

Depending on if you’re planning on the cylindrical or the powell lens illumination paths, there will be a different set of threaded holes to fix the PY004 onto the baseplate with, highlighted in the image below. The large 3-hole pattern on the top of the PY004 should align directly with the three threaded holes on the baseplate. Screw 1/4” screws into these holes to secure the PY004 in place.

Figure 2: Location of the holes used to secure the PY004 onto the baseplate depending on if you’re doing an powell or cylindrical lens system

Step 3: Secure the voicecoil to PY004 adapter onto the PY004

Using 1/4” screws in the 4 holes on the adapter, tighten the screws until the adapter is secured in place onto the PY004.

Figure 3: Placement of the voicecoil adapter on the PY004

Step 4: Secure the voicecoil to the adapter using the front screw holes

Using 8/32” screws, secure the voicecoil onto the front of the adapter using the two thru-holes on the front of the adapter.

Figure 4: Completed voicecoil assembly

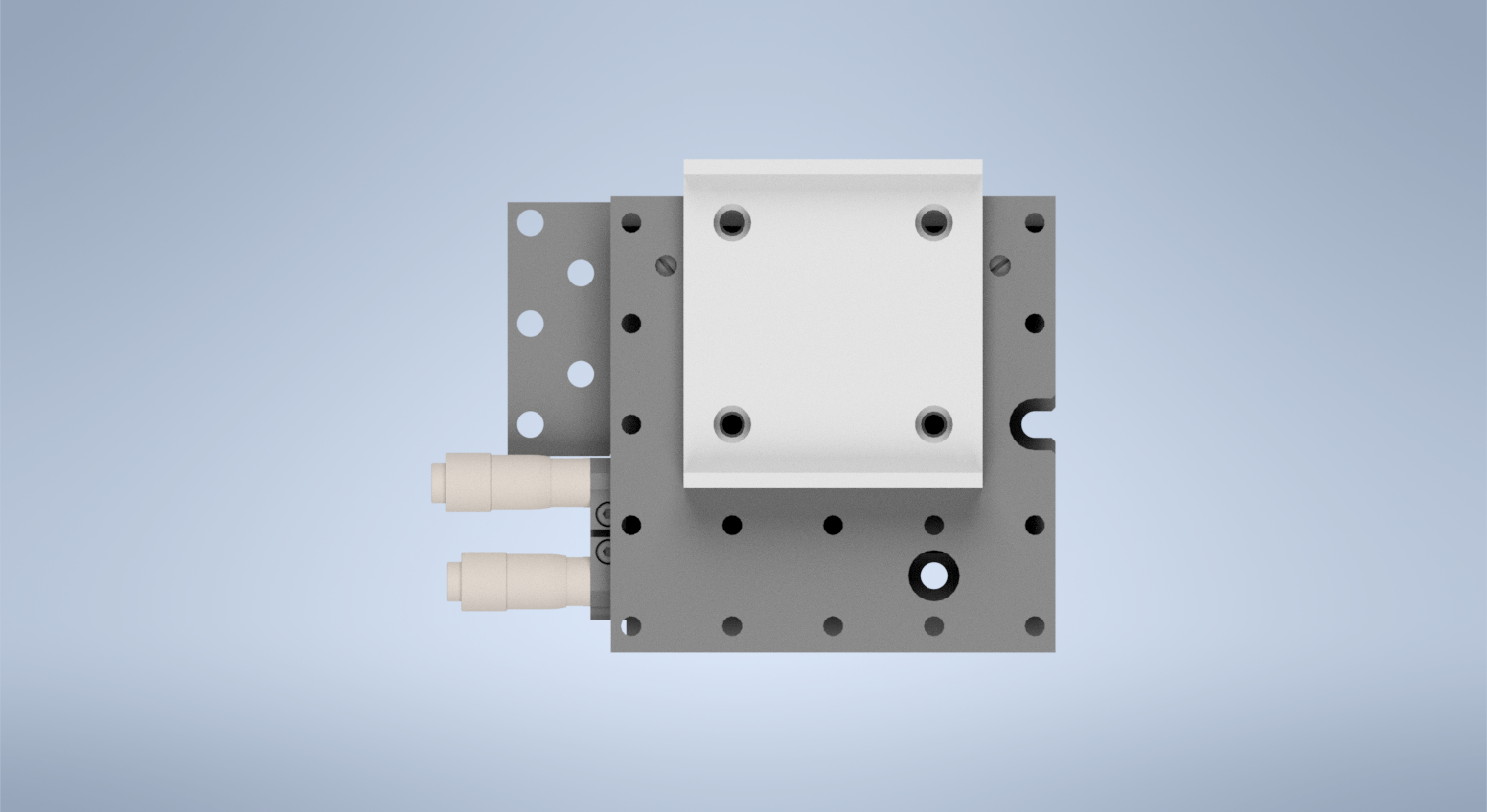

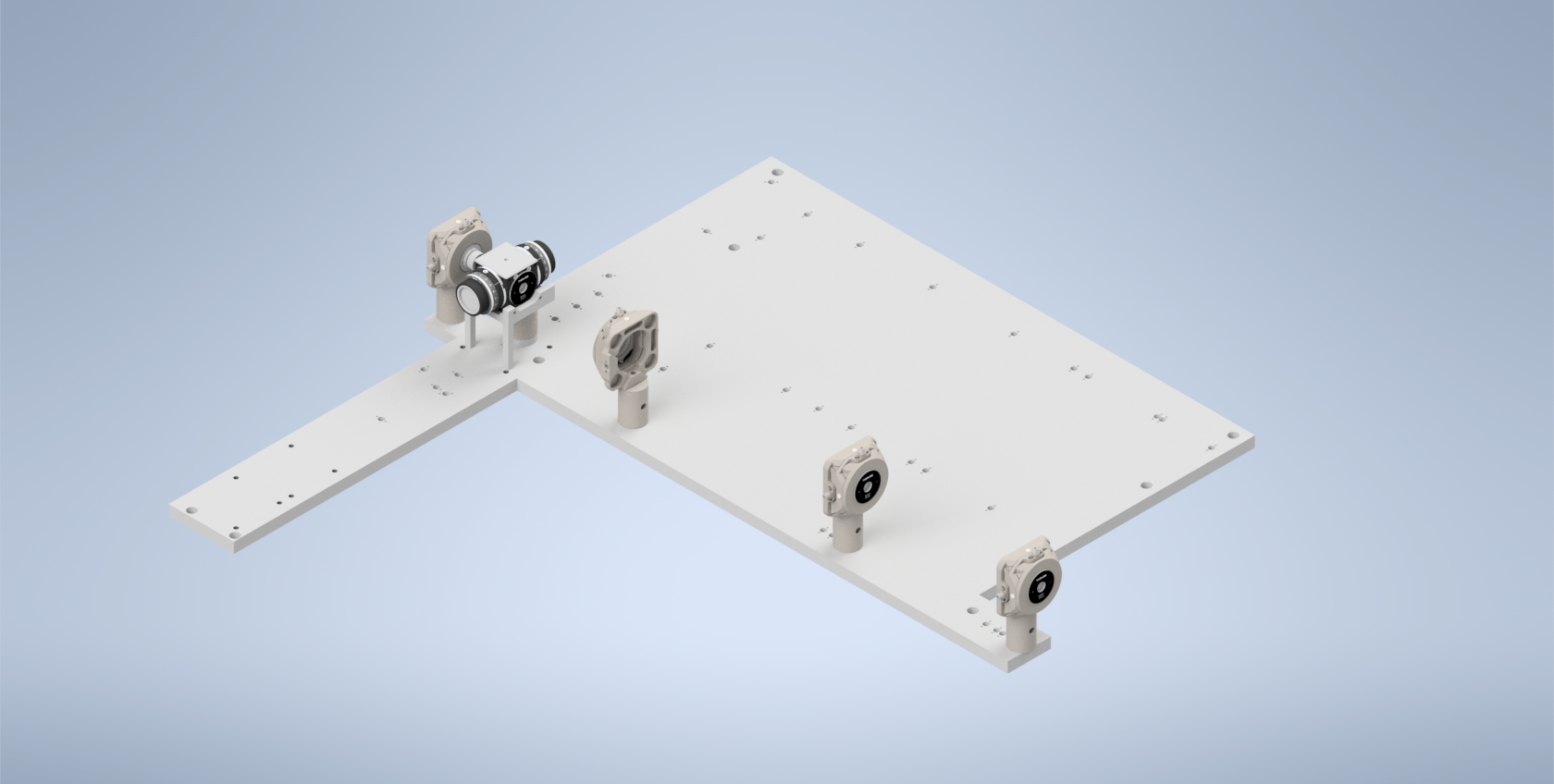

Detection Path Assembly

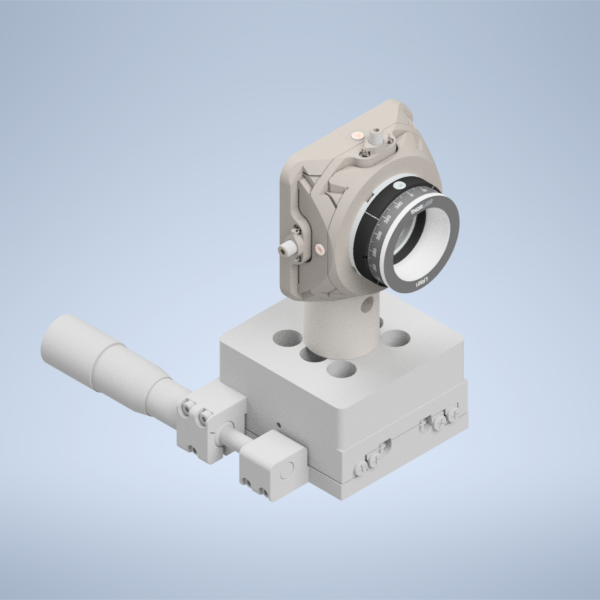

Our detection path consists of our Nikon N25X-APO-MP detection objective, Hamamatsu ORCA Flash4.0 V3 Camera, ASI C60-TUBE-400 tube lens, and ASI FW-0002-8 8-position filter wheel unit. These components are mounted together and affixed onto an ASI LS-100-AMCCH translation stage for focus control. We currently use a prototype detection path baseplate (available here) as a mounting stage for these elements and the sample chamber; however, this additional baseplate is still undergoing design iterations and is not critical for a functional detection path.

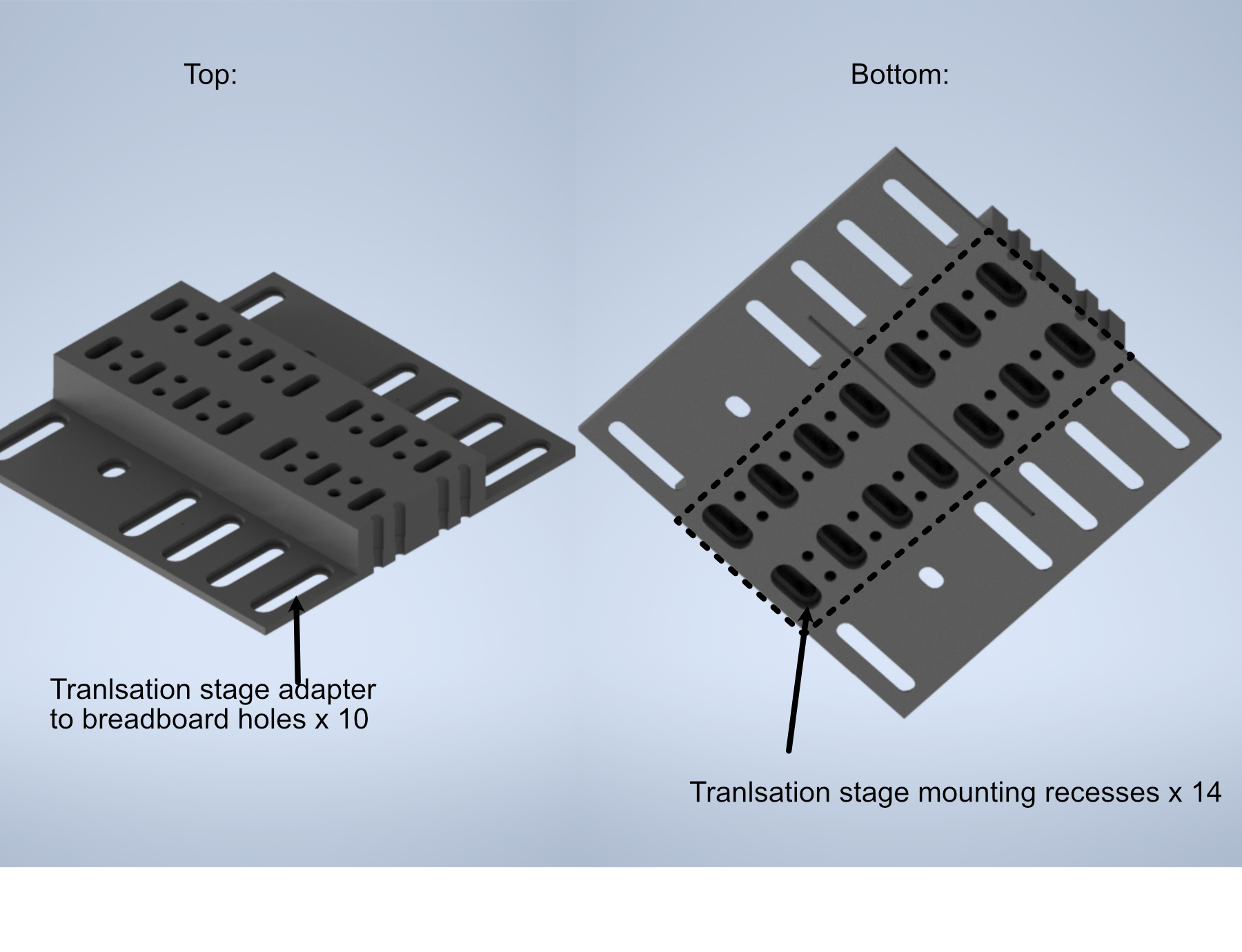

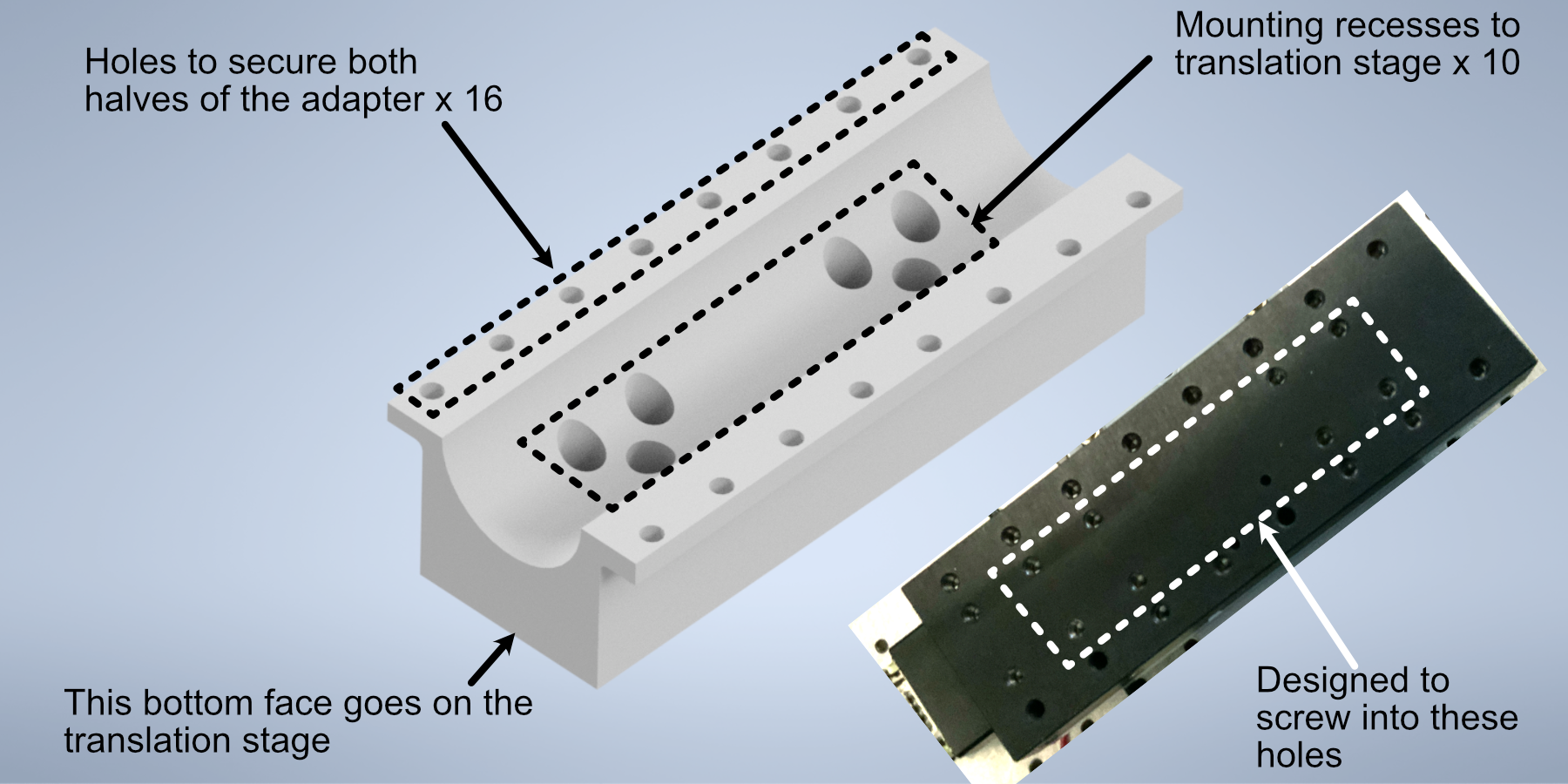

We utilize two additional custom adapter elements in the construction of the detection path: a shell casing around the tube lens that mounts to the translation stage and an adapter for the translation stage to mount it to an optical breadboard table. The height thicknesses of these elements were chosen such that the height of the detection objective center should match that of the illumination objective (which with the 1.5” tall posts our illumination baseplate rests on is 4.75” above the optical table surface). These elements can be custom machined if desired; however, we have found 3D printed PLA variants to perform their functions effectively as well.

The assembly of the detection path begins with the translation stage and it’s associated breadboard adapter (available here in two variants, based on whether or not one is using the 0.5” thick detection path baseplate):

Turn the translation stage upside-down

Place the breadboard adapter upside-down on top of the inverted translation stage (such that the raised platform of the adapter is touching the bottom side of the translation stage)

Align the recesses on the bottom of the adapter with the holes on the bottom of the translation stage

Fix the adapter onto the translation stage by screwing M6 screws into the recesses aligned with the translation stage holes.

Figure 7: Schematic of the translation stage breadboard adapter

The next step is flipping the translation stage assembly right side up again, and then fixing the first of two halves of the tube lens adapter onto the top of the translation stage:

Place the tube lens adapter half onto the top of the translation stage such that the block with two sets of five recessed holes is touching the top of the translation stage.

Align the Recess holes on the adapter with the holes on the top of the translation stage.

Fix the adapter onto the translation stage by screwing M6 screws into the aligned recess holes

Figure 8: Schematic of the tube lens to translation stage adapter

Next, we’ll focus on assembling the tube lens and filter wheel:

Take the MIM to Filter wheel adapter and fix it onto the front port of the filter wheel using the associated screw ports

With the adapter fixed, now screw the 400 mm tube lens into the adapter.

Figure 9: Schematic of the filter wheel port for the tube lens

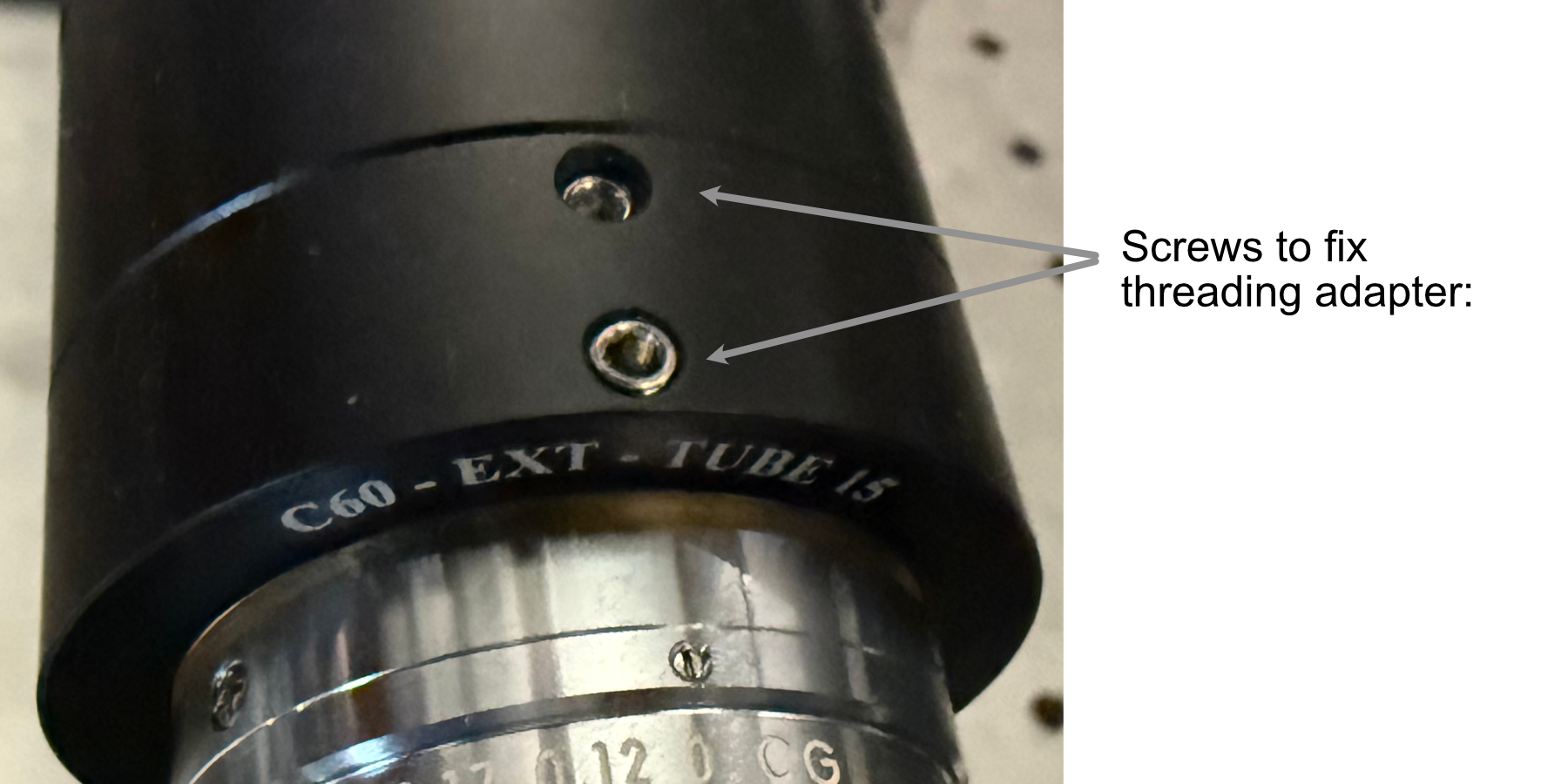

- In order to fix our detection objective onto the tube lens, we must first prepare an extension and threading adapter:

Take the C60-EXT-15 15 mm Tube extension piece and place the RAO-0051 M32x0.75 threaded sleeve inside

Using the screws on the top of the extension piece, fix the threaded sleeve in place

Insert/screw the extension piece into the front of the tube lens.

Figure 10: Showcase of the screws used to secure the thread adapter for the tube lens

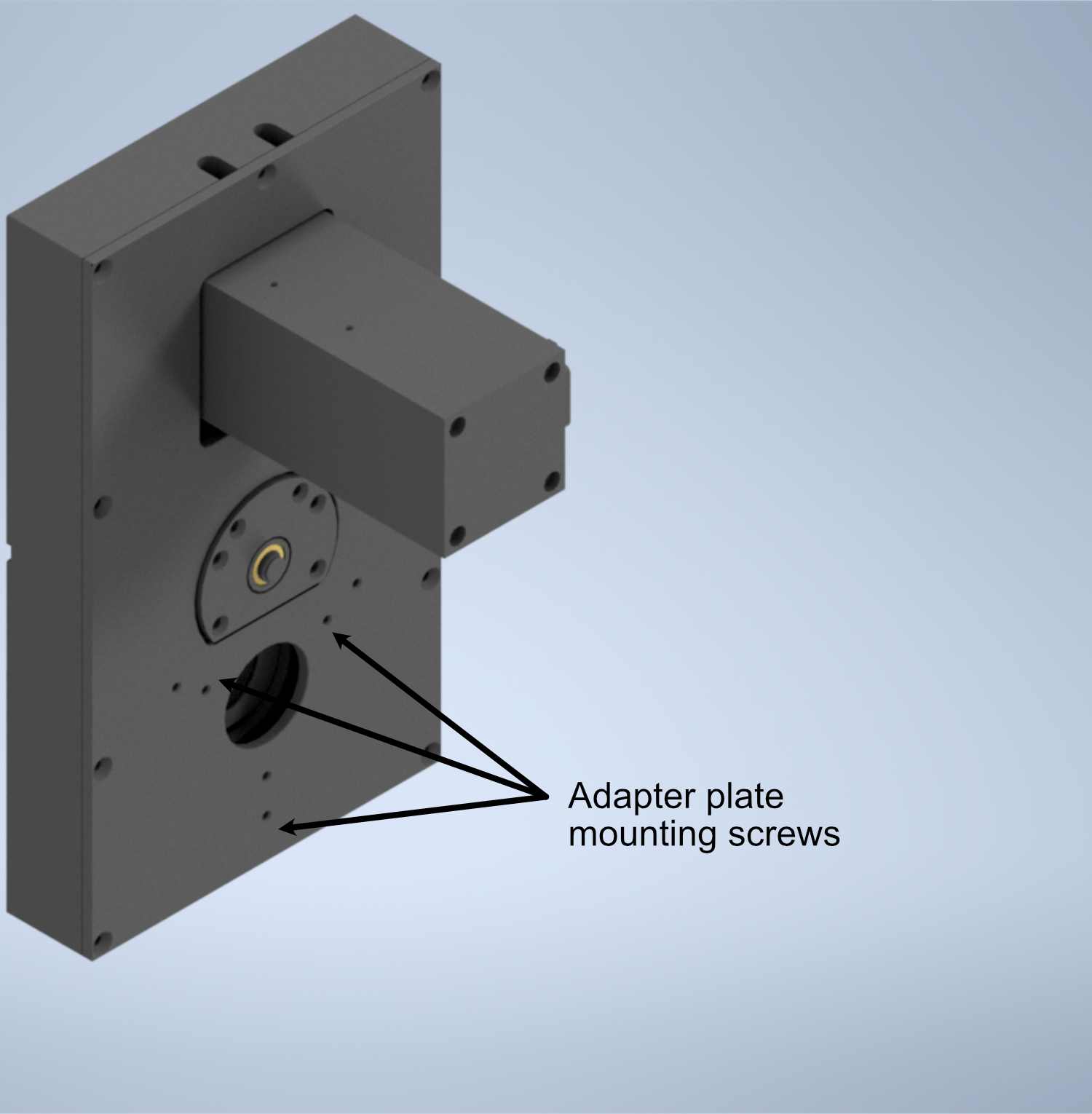

- The tube lens assembly is now ready to be fixed onto the translation stage assembly:

Place the tube lens assembly such that the tube lens lies within the curved region of the tube lens adapter

While there isn’t an exact science to the relative placement of the tube within the adapter, try to position it such that more of the tube is extended out on the side where the objective will be mounted (our setup is shown below for reference).

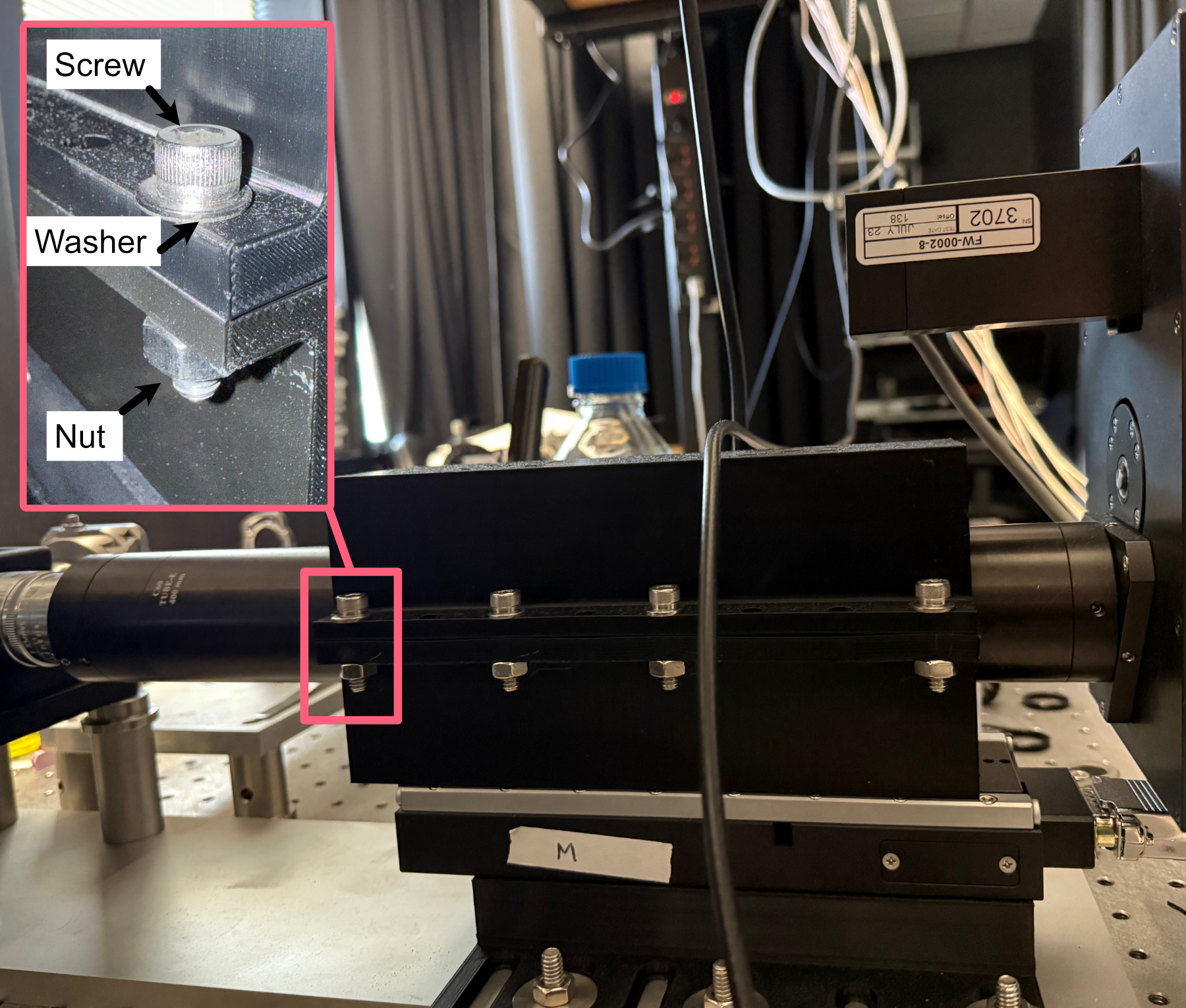

Place the second half of the tube lens adapter such that the curved side fits onto the lube lens and position it such that the holes of both halves of the adapter align with each other.

Using your choice of either M6 or 1/4”-20 screws and associated washers/nuts, place the screws with a washer placed on them first into the aligned holes of the adapter. We used 4 of the adapter holes on each side, but more can be used for extra security if desired.

Screw a washer onto each of the screws until they’re secured against the bottom lip of the adapter.

Figure 11: Example of tube lens mounted in the corresponding adapter

The detection path assembly can now be fixed into place onto either the detection path baseplate or the optical table, keep in mind this process is meant to essentially place the unit in the ballpark of where it should be, finer adjustments will be made afterwards:

Using the mounting holes on the translation stage assembly, place the assembly such that the edge of the translation stage adapter facing the illumination path is roughly 9-10” away from the location of the illumination objective.

Using the adjacent edge of the translation stage adapter (the one that should be perpendicular to the orientation of the illumination path), try to align the side of the adapter with the mounting hole of the illumination objective.

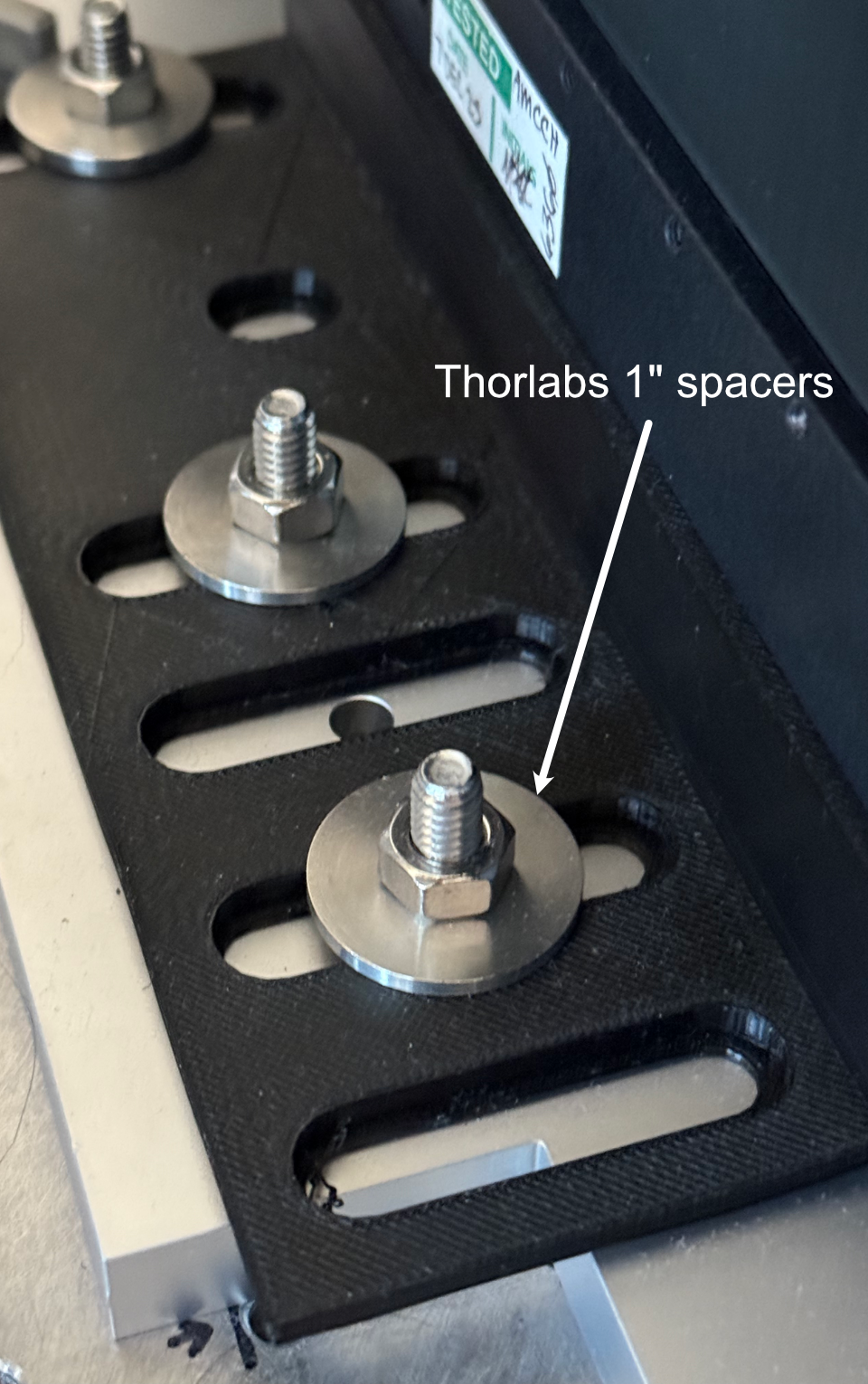

Screw the translation stage adapter into either the optical table to the detection path baseplate (we recommend using Thorlabs 1” Spacers in place of washers here).

Figure 12: Setup for securing the translation stage to breadboard adapter onto our detection path baseplate

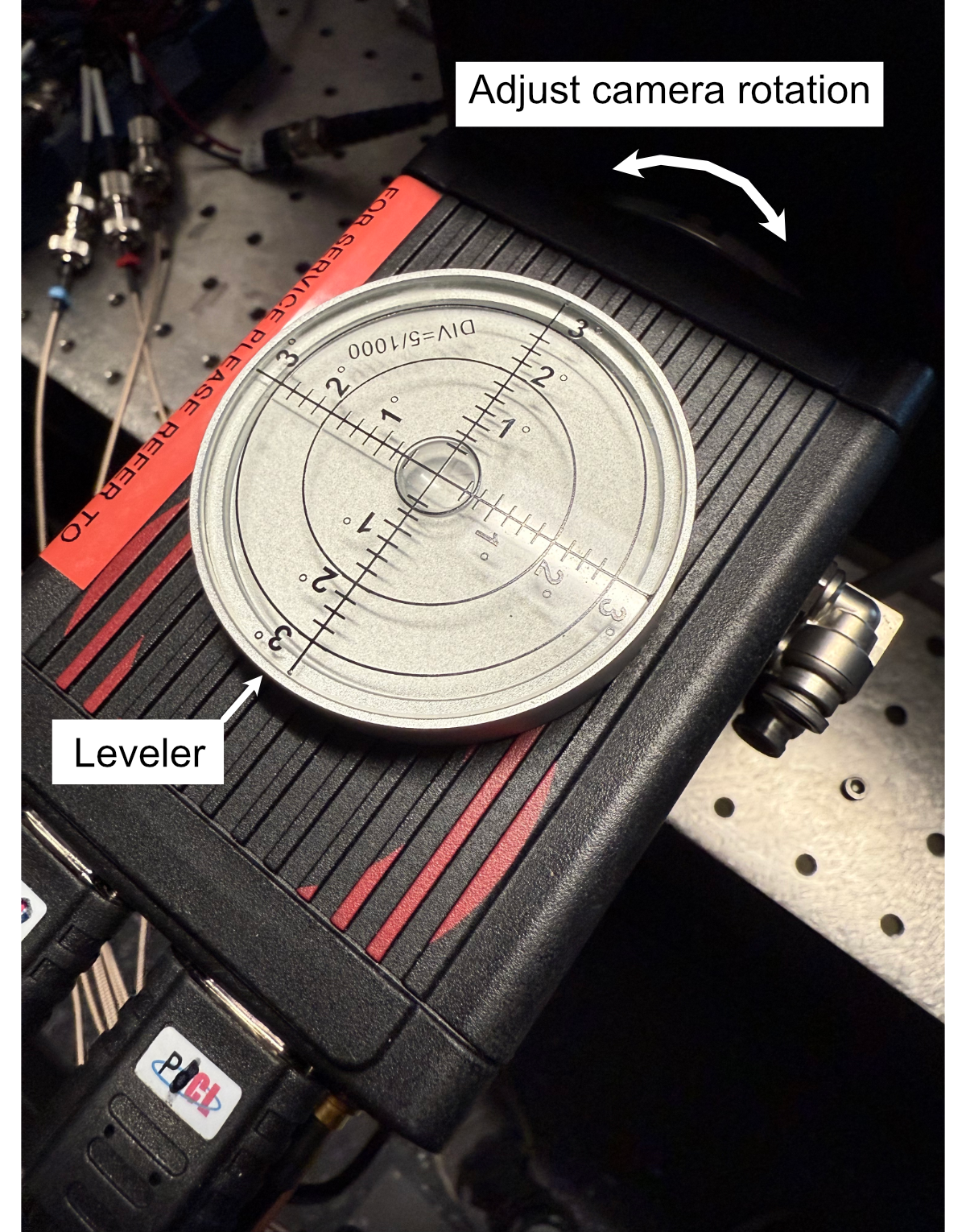

- With the assembly fixed in place, the camera can then be screwed into the filter wheel:

Align the front thread of the camera with the back port of the filter wheel

Screw the camera into the filter wheel until there is resistance

Slowly adjust the camera tilt until the top surface is leveled (we use a bubble leveling tool for this, shown below)

Figure 13: Mounting of the camera

The final steps to to assemble the detection path are to screw the detection objective into the front of the tube lens and attach all associated wires to the camera, filter wheel, and translation stage. If there’s not enough clearance between the front of the tube lens and the sample chamber to screw in the detection objective, the translation stage might need to be wired up first and translated backwards manually using either navigate or the Tiger Control Panel software.

Assembling the Sample Chamber

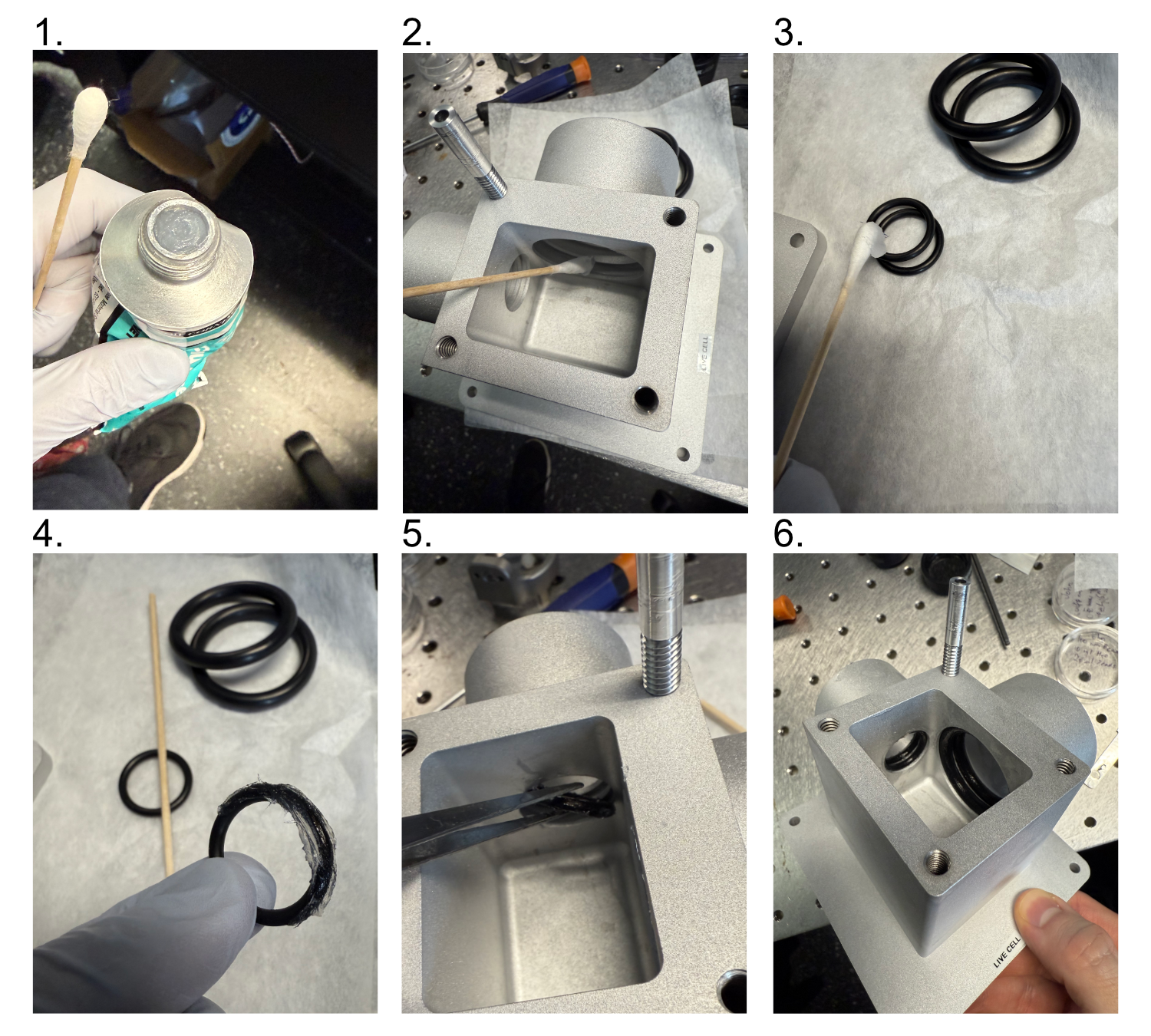

In order to ensure a watertight seal around our objectives, both of our objective ports feature two sets of o-rings surrounding their circumference. For our smaller port associated with the TL20X-MPL objective, we use oil-resistant Buna-N O-Rings with 11/16” inner diameter (ID) and 13/16” outer diameter (OD). For the larger port associated with the Nikon 20X objective, we used Buna o-rings with roughly 1.3” ID and 1.7” OD. These o-rings and their associated grooves are first coated with vacuum grease in the following process:

Unscrew vacuum grease container

Using either a finger or a cotton-tipped applicator, apply a layer of vacuum grease into and around the grooves on both ports

Put more vacuum grease on the cotton-tipped applicator

Using a finger or cotton-tipped applicator, take an o-ring and coat it fully in the vacuum grease.

Place the o-ring in the appropriate groove using a finger or tweezers to help ensure it sits within the groove

Repeat steps 3-5 for all 4 o-ring grooves in the chamber

Figure 4: Preparation and Placement of O-rings in the Sample Chamber

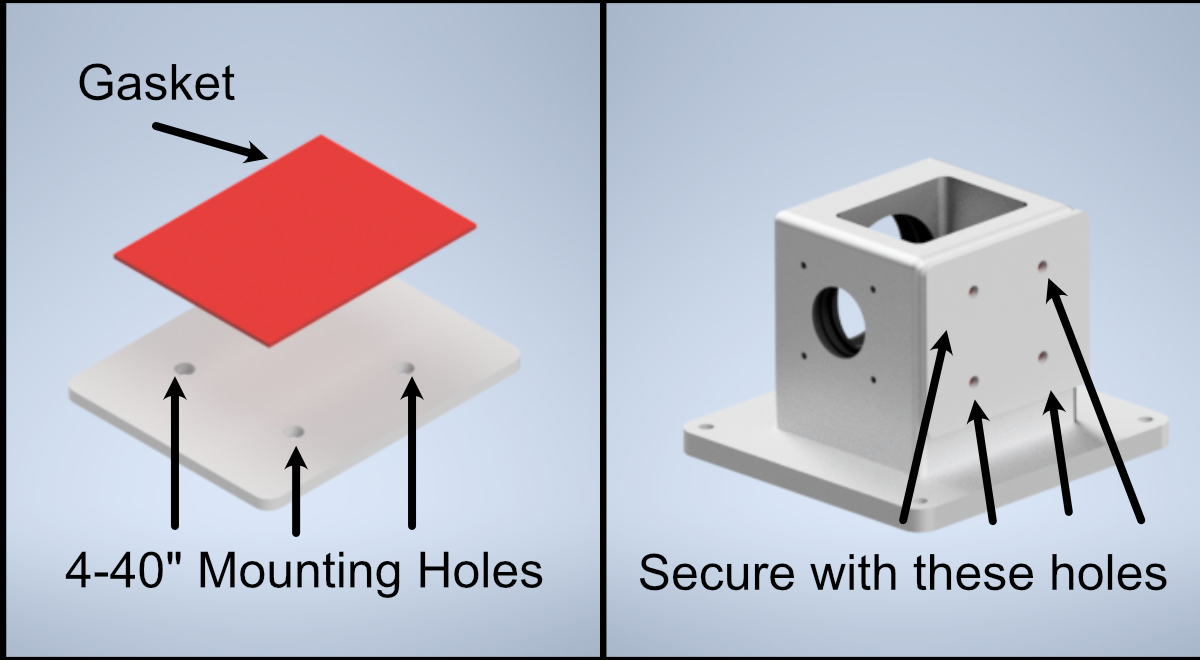

Then with the o-rings in place, if you’re using a sample chamber variant that offers two detection path configurations (traditional orthogonal and transmissive), install a gasket and gasket retainer on the transmissive port:

Cut a gasket sheet into a roughly 2x1.5” rectangle gasket section.

Place the gasket onto the gasket retainer, poke a marker through the 4 holes on the gasket retainer to mark where the screw holes will be.

Use scissors or another tool to make cuts at each of the 4 marked locations on the gasket, such that a 4-40” screw is able to pass through them.

Align the gasket over the gasket retainer and place 4 4-40” screws into each of the holes such that the threading pokes out from the gasket side.

Align the gasket assembly screws with the sample chamber transmissive port threaded holes, fully screw in the screws into the sample chamber holes.

Figure 4: Preparation and Placement of the gasket and gasket retainer on the sample chamber

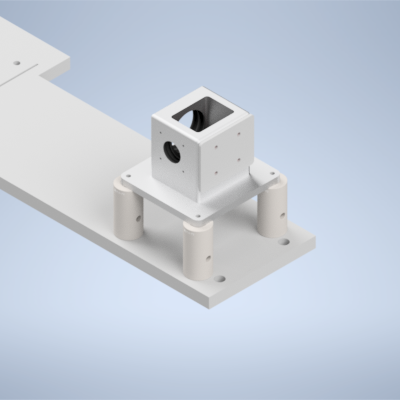

Now fix 4 2.5” posts onto the corresponding holes on the detection path baseplate, and then secure the sample chamber onto those posts using the four 8-32” holes on the base of the sample chamber.

Figure 4: Placement of sample chamber assembly onto detection path posts.

Alignment

Alignment Overview

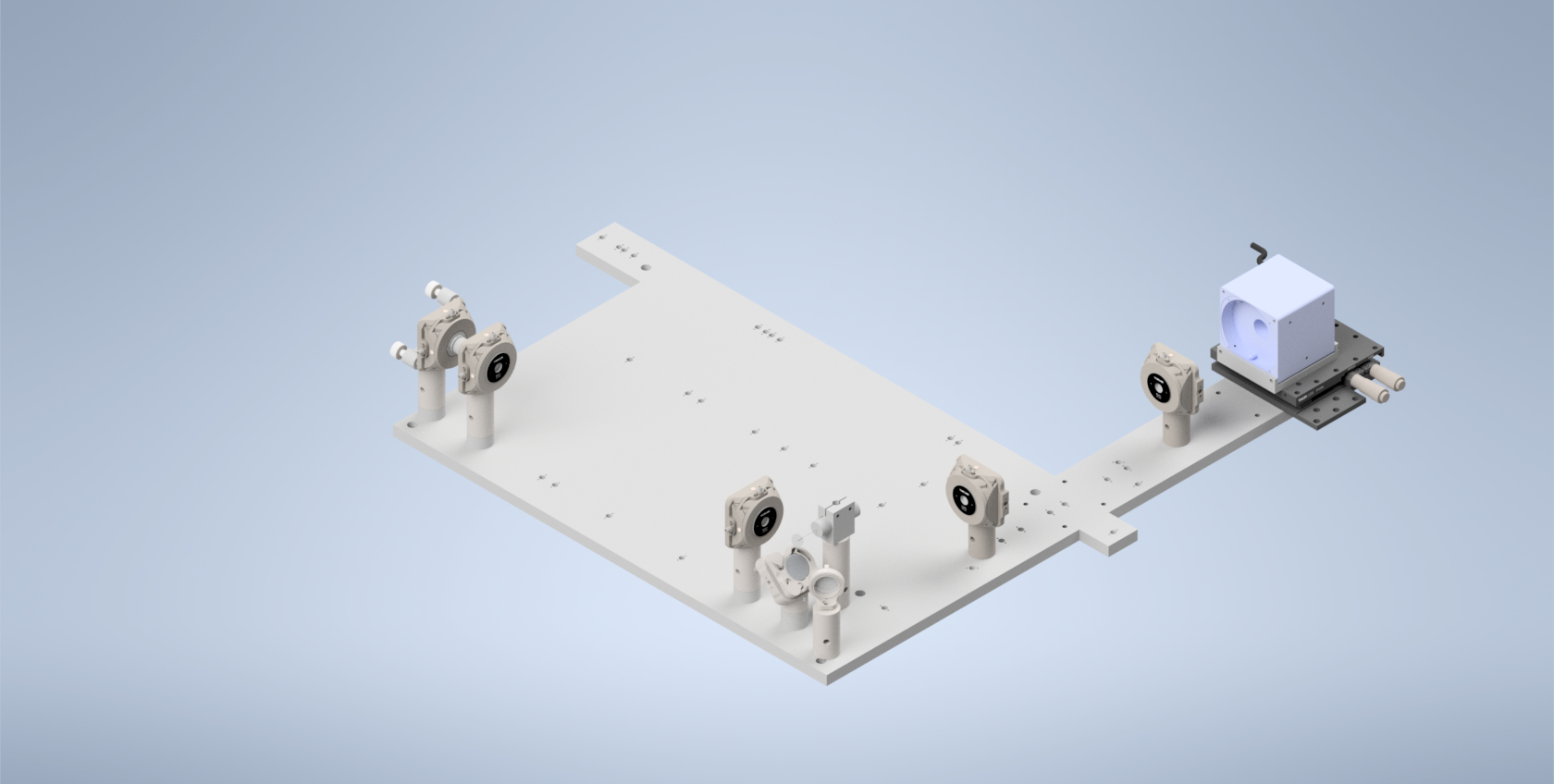

For the second iteration of our Altair baseplate system, the construction and alignment process is more involved than our first iteration, but should still be a straightforward step-by-step process. To make things a little bit easier, the system is first aligned and optimized without the presence of some of the lenses (L1, L2, L3, L4, L5 for the Powell lens configurations), and then the rest of the lenses are added in and the system is recalibrated.

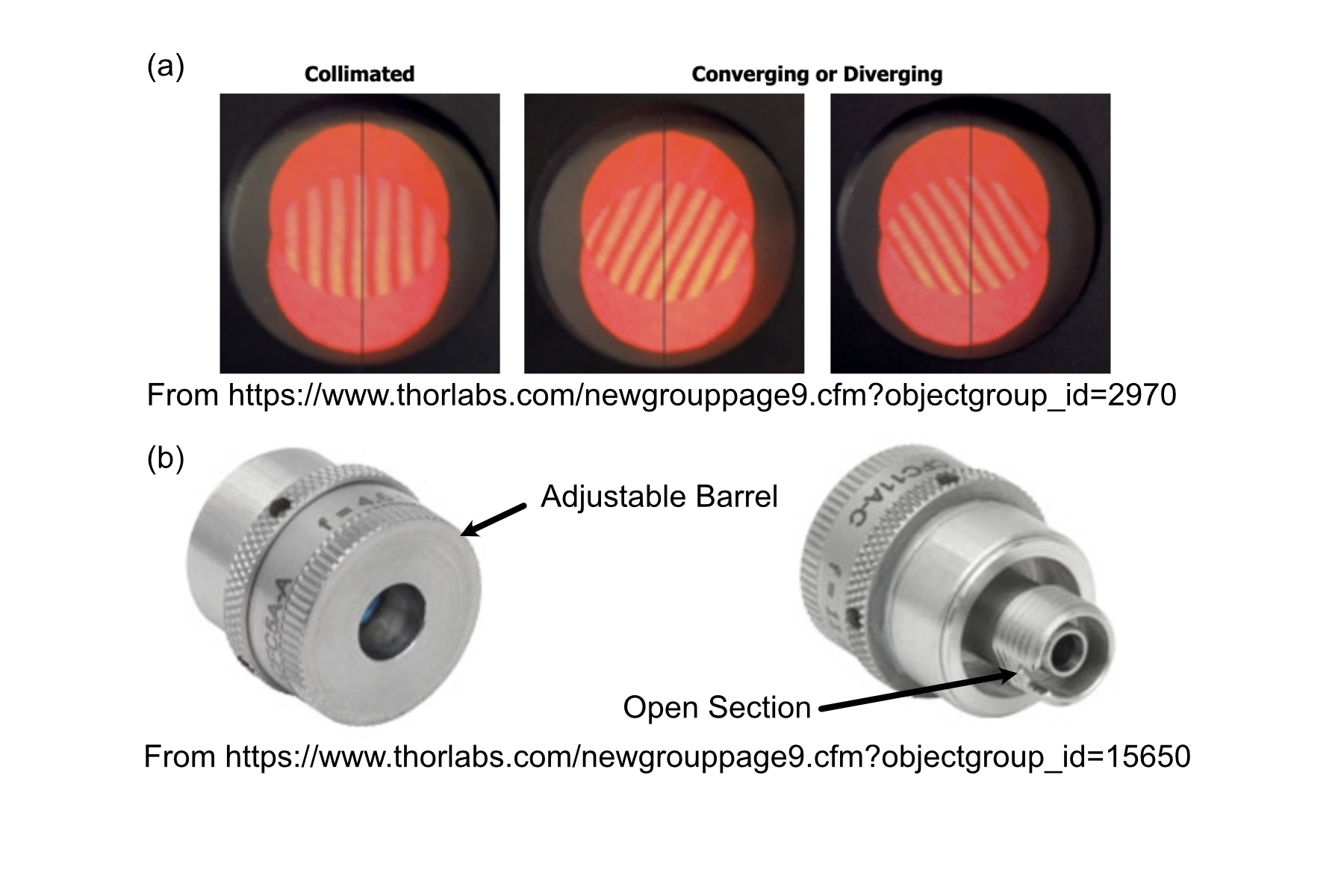

Step 1: Laser Collimation

When first assembling the system, ensuring proper output collimation from the fiber laser source is critical. There are multiple checks that one can take for this step, but we utilize a combination of a shear-plate interferometer and two pinhole apertures placed at opposite ends along the length of the baseplate. Shear-plate interferometers are designed to split and interfere an input beam of coherent light, such that when the beam is collimated there are interference fringes aligned vertically with a reference line. The fiber laser collimator we used for this system is the Thorlabs CFC11A-A, which features an adjustable barrel which controls the position of collimation optics within the element.

The basic assembly process involves first inserting and fixing the CFC11A-A into a Thorlabs AD15S2 adapter, which allows it to then be mounted into a 2.5” Polaris K1XY mount. This assembly is then mounted onto the respective Polaris post at the start of the baseplate. The fiber laser source is then able to be directly mounted into the CFC11A-A, making sure that the protrusion on the fiber wire aligns with the open section of the CFC11A-A port. The basic process of ensuring collimation then involves turning on the laser source, and placing the shear-plate interferometer such that the input port aligns with the output of the laser unit. Then, by slowly adjusting the barrel of the CFC11A-A and observing the interference fringe orientations along the top display of the interferometer, one is able to adjust the beam until it is properly collimated.

Figure 1: Shear Plate interferometer and collimator lens

Step 2: Beam Walking 1

Section Goal: Ensure that the beam is traveling parallel to the baseplate surface and through the center of all mounted elements up to the RFO location (part 1).

With the beam properly collimated, we can begin the series of steps to walk the beam such that it is both centered on all of our optical elements as well as runs parallel to the surface of the baseplate. Then place one 2.5” Polaris post at these three locations: the hole corresponding to the Powell lens, the hole corresponding to L4, and the hole corresponding to the remote focus objective (RFO) location. Then place 1XY mounts on each of those 2.5” Polaris Posts . Then screw SM1-threaded adjustable irises (SM1D12) into those 1XY Mounts. Then place a 1” mirror in a Polaris B1F mount and mount it on a 3” optical post in the 45 degree oriented mounting position on the board as shown in the image below. With the irises and mirror in place, this step becomes and iterative process of adjusting the XY and Tip/Tilt of the laser K1XY mount until the beam passes through the center of all irises and roughly onto the center of the mirror. As a general direction, starting with the irises opened more and then steadily closing them further as you refine the tip/tilt and XY of the K1XY is recommended. If adjusting the tip/tilt of the K1XY becomes a bit overwhelming, it might be helpful to screw all of the tip/tilt knobs on the mount fully in, such that the starting point that you’re working from should be roughly flat (perpendicular to the surface of the baseplate).

Figure 2: Beam Walking 1

Step 3: Beam Walking 2

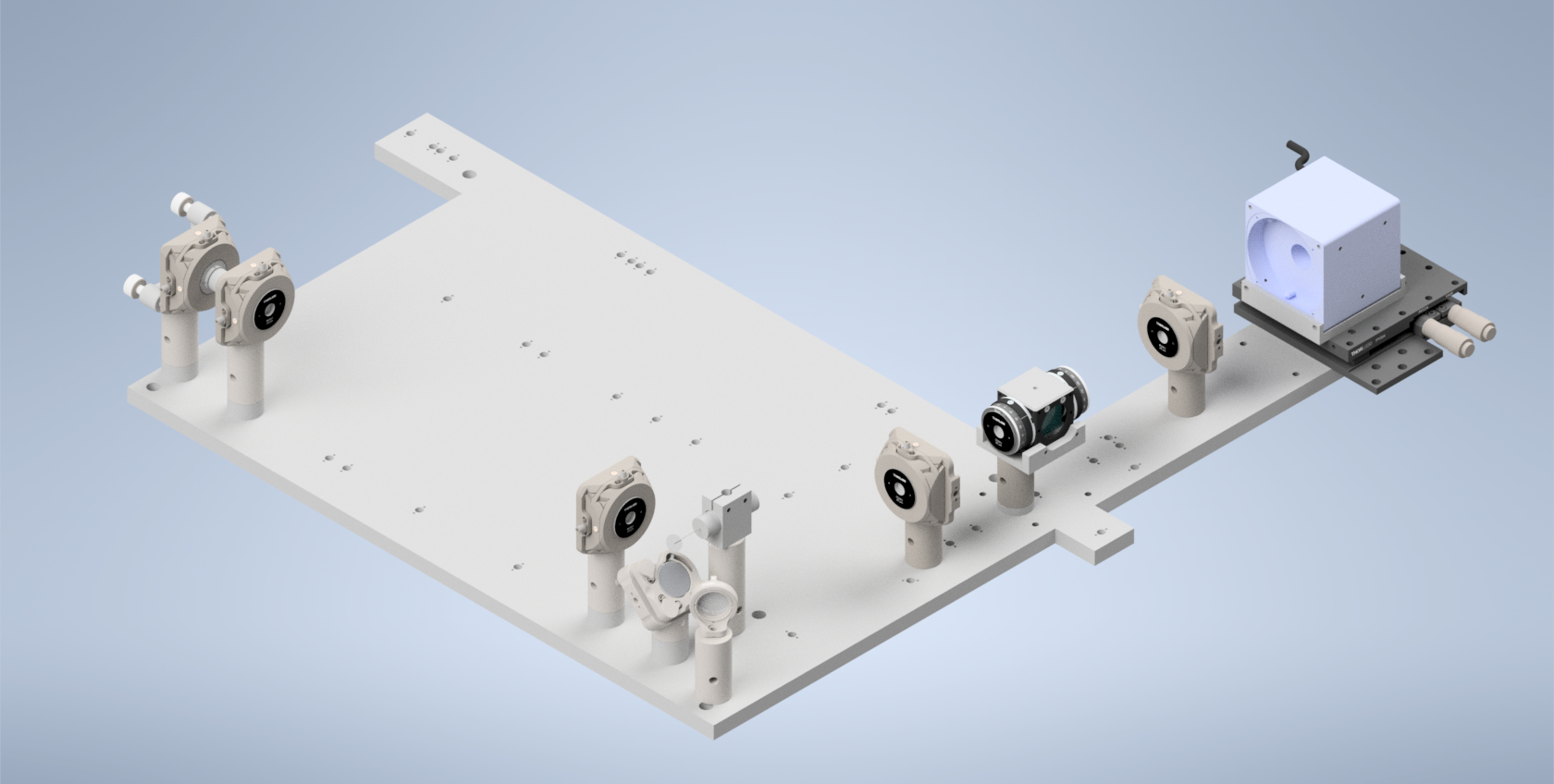

Section Goal: Ensure that the beam is centered on the galvo and K1S4 mirror, and that it travels parallel to the baseplate surface and through the center of all mounted elements up to the RFO location (part 2).

Next, assemble and add in the resonant galvo and the K1S4 mirror directly underneath it. Then replace the post of the 45 degree B1F mirror to be 2” instead of 3”. Then place two 1XY mounts on 1.5” posts, one at the location of the RFO and one at the location of L5. Then place and screw in the PY004 onto the baseplate and then mount the voicecoil adapter on top as shown below (have graphic that shows the location of the voicecoil mount on the PY004). Then mount the voicecoil (Link assembling voicecoil section) onto the adapter, making sure the side with the mirror is facing towards the beam path. The iteration flow here will be to adjust the tilt of the resonant galvo until the beam is centered on the K1S4 mirror underneath it, and then adjust the tip/tilt of the K1S4 mirror until the beam is centered on the B1F mirror and the two irises after. Then adjust the tip/tilt on the PY004 of the voicecoil until the back-reflected beam spot passes through the irises on it’s return path.

Figure 3: Beam Walking 2

Step 4: Beam Walking 3

Section Goal: Place the beamsplitter in the system, ensure it’s oriented correctly.

Assemble the beamsplitter, it’s mount, and the 1.75” Polaris post it rests on, and mount it on it’s corresponding hole (show the orientation of the beamsplitter). Ensure that the beamsplitter is oriented such that the beam is passing through both sides (you can use pinholes to irises for this step, they should screw into the SM1 threading on the beamsplitter).

Figure 4: Beam Walking 3

Step 5: Optional Beamsplitter Alignment

Section Goal: Use the alternative laser launch hole to ensure that test beam goes straight through the beamsplitter return path to the center of the ILO.

Mount three Polaris 1XY units on 1.5” posts along the return path at the location of L6, L7, and the illumination objective (ILO), respectively. Then mount a 1.5” post and Polaris 1XY unit on the hole denoted for the alternative laser launch. Screw the laser (Thorlabs CPS532) into the Polaris 1XY mount. With each of the 1XY Mounts roughly centered in both X and Y, ensure that the laser beam passes through the center of all elements using a frosted pinhole or iris installed in them.

Figure 5: Beamsplitter Alignment

Step 6: Beam Walking 4

Section Goal: Install polarizers and ensure that the beam is traveling properly on its return path through the beamsplitter.

Start by threading an LRM1 rotation mount into both the side of the beamsplitter facing the RFO and the side opposite facing L5. Then thread the half-waveplate into the L5 side and the quarter-waveplate into the RFO side.

Rotate the half-waveplate to make the beam as bright as possible in the direction of the RFO, then adjust the quarter-waveplate to make the beam as bright as possible on the return path in the direction of the ILO.

Ensure that the return beam properly travels back through the beamsplitter and down the path to the ILO. Adjust tip/tilt of voicecoil mirror to manipulate the direction of the beam.

This establishes a ground-truth beam position for the next step where we add in the RFO.

Figure 6: Beam Walking 4

Step 7: Beam Walking 5

Section Goal: Add in RFO, do initial alignment.

Added RFO back in, then adjusted the XY on the mount for the RFO until the back reflections from the RFO were aligned (same method, put a pinhole card behind RFO and center the pinhole on the beam)

Figure 7: Beam Walking 5

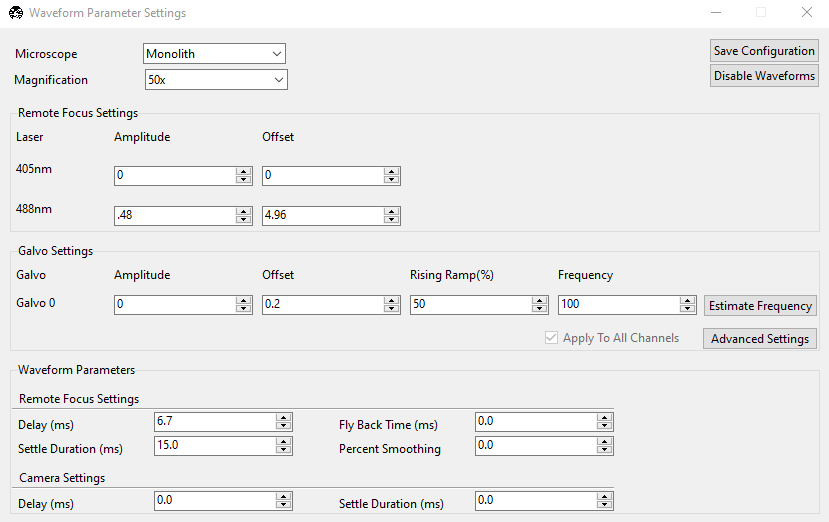

Step 8: RFO Offset

Section Goal: Install L6 and L7, Adjust the RFO offset in navigate such that it’s collimated between the beamsplitter and L6 and L7 and the ILO.

Start by installing SM1A2 threading adapters onto the Polaris 1XY mounts corresponding to L6 and L7. Then thread both L6 and L7 into their respective mounts, such that the Thorlabs label on them is on the side farthest away from the 1XY mounts, shown above in the “Breakdown of Baseplate Holes” section.

With a shear-plate interferometer placed between the beamsplitter and L6 (and then L7 and the ILO), adjust the RFO offset in navigate (leaving the amplitude at 0 for now) until the light between the beamsplitter and L6 and L7 and the ILO is collimated. The available range should be between 1 to 10, with the optimal value varying for each system, for our initial system this value was around 5.

Figure 8: The Waveform Parameters panel in navigate.

Step 9: Add In Lenses

Section Goal: Add in the rest of the non-Powell lenses into the illumination path.

Install L2, L3, L4, and L5 into their respective B1S holders, and then screw those holders into their correct

If beam is no longer centered on the RFO, Remove the RFO from the path, and focused on adjusting the tip/tilt of the voicecoil mirror to have the return beam be centered on both the first TL mount after the beamsplitter on the return path as well as the ILO objective mount (using irises or frosted pinholes)

Added RFO back in, then adjusted the XY on the mount for the RFO until the back reflections from the RFO were aligned (same method, put a pinhole card behind RFO and center the pinhole on the beam)

Then add in TL1 and TL#2, adjust the rotation and XY of TL2 to make the beam on the ILO centered again, use shear plate and change VC offset to get beam re-collimated Using the re-collimated offset position as the baseline, adjusted the detection path (ensuring it’s as perpendicular as can be to the illumination path), and primarily adjusted TL1 and TL2 XY’s to center the beam as much as possible on the back of the ILO

Step 10: Install Detection Path

Section Goal: Assemble/incorporate detection path into the setup, ensure it’s centered on the beam by using the chamber filled with water and fluorescein.

First assemble the detection path.

Step 11: Optimize System Light-Sheet Performance

Section Goal: Optimize navigate parameters and XY offsets of RFO, L6, L7, and ILO to verify the system is working.

Step 12: Add in Powell Lens

Section Goal: Incorporate Powell Lens, do a final fine-tuning alignment of system elements.

Troubleshooting

Optimizing Lens Placement/Orientation Using Backreflections

Test

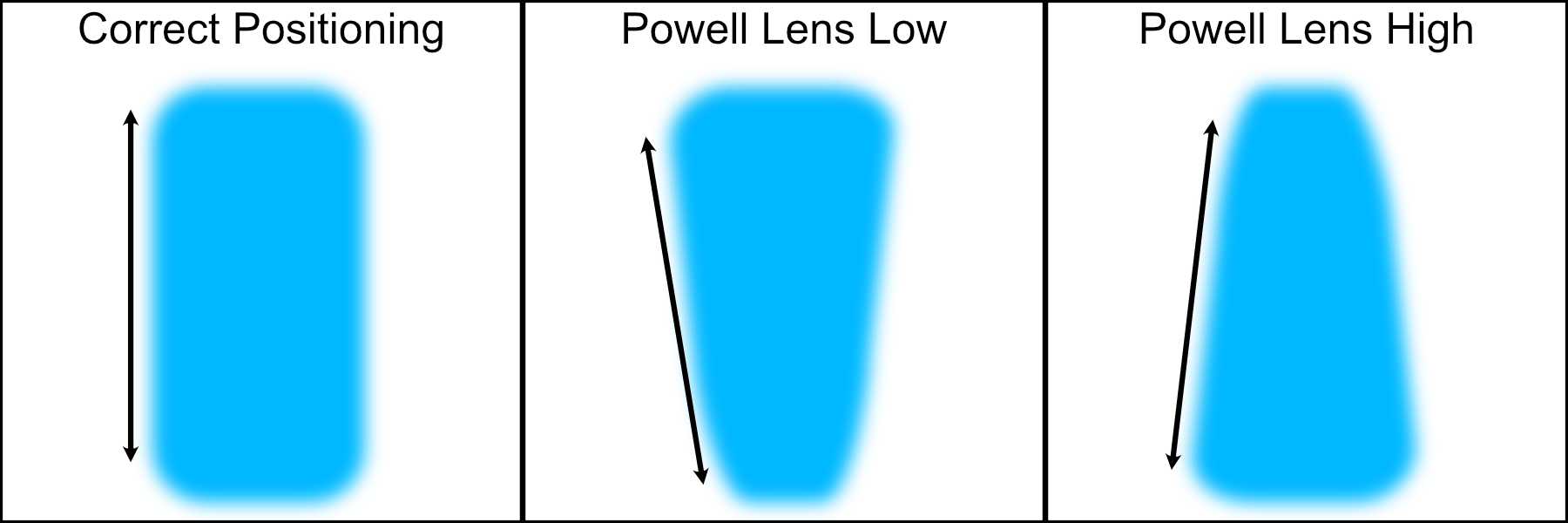

Optimizing Powell Lens Placement

The placement of the Powell lens in the optical path takes a bit of fine-tuning compared to some of the other lenses in our system. The lens itself is particularly sensitive to displacements in x and y, where if it’s off it is easily visible in the profile of the beam on the front surfaces of the lenses that follow. Using the beam profile on the front of L2 as an example, when the Powell lens has a vertical (y) displacement, the beam profile starts to take on more of the conical shape instead of the more rectangular or pill-shaped profile from our simulations.

Figure 1: Potential misaligned Powell lens beam profiles on the front surface of L2

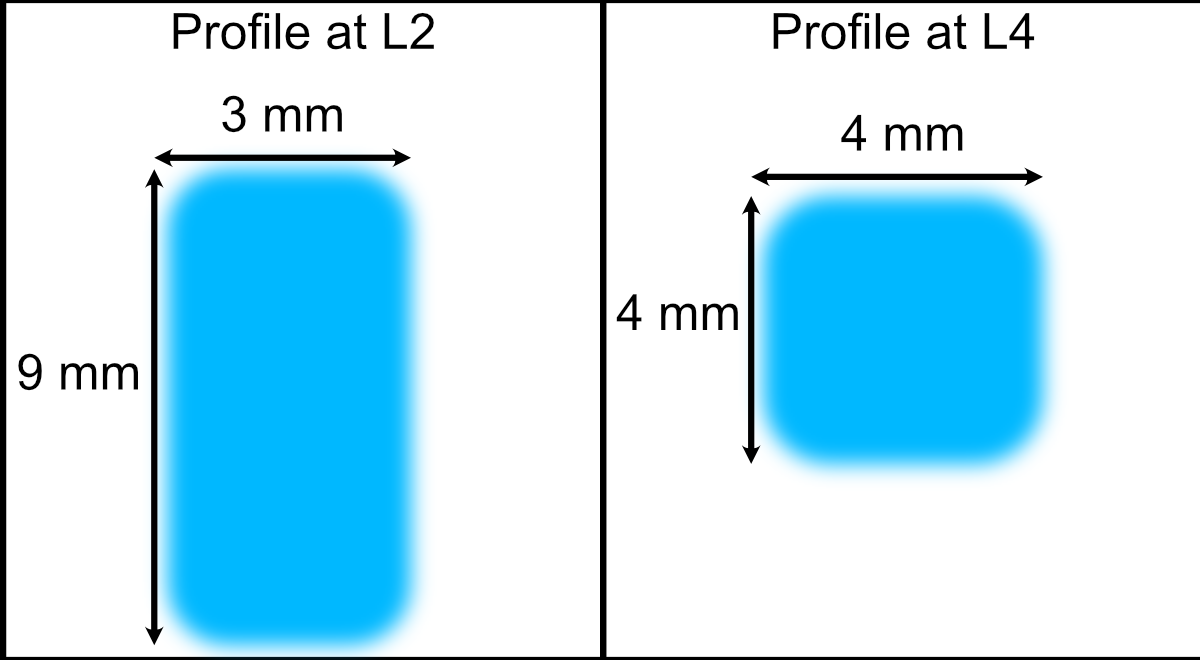

In addition, due to tolerances with the Powell lenses we use in simulation compared to the physical ones purchased, there can be an additional z offset needed between the Powell lens and L2 for the beam profile to match simulations. In our particular case, we found that having an additional 2.6 mm spacing between the Powell lens and L2 made the rest of the system follow closely with our simulations, but this value might be different for different Powell lenses. We found this optimized spacing value by observing the beam profile on the front of L2 and L4, comparing it to simulated profiles in the same locations, and iteratively adjusting the LNR25M dial until the profiles matched closely.

Figure 2: Example profiles at L2 and L4 front surfaces used to optimize z-displacement of L1